Micro 3D models

EGR metal connection pipe • Micro II

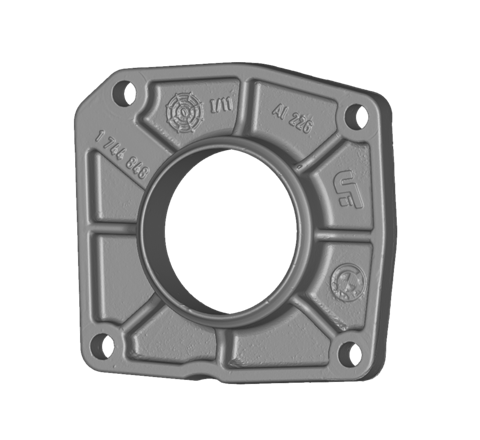

Industrial part • Micro II

Beetle • Micro

Socket cap screw • Micro

Jaguar ring • Micro

iPhone 4S SIM card tray • Micro

Heart pendant • Micro

Gemstone • Micro

Clamp • Micro

Squirrel skull • Micro

Shampoo bottle cap • Micro

Drain Weasel wand connector • Micro

Electrical outlet • Micro

Screw • Micro

Copper key • Micro

Plastic bolt • Micro

Metal nut • Micro

Pipe bend • Micro

Plaster cast of teeth • Micro