Leo 3D models

Pipeline segment • Combo

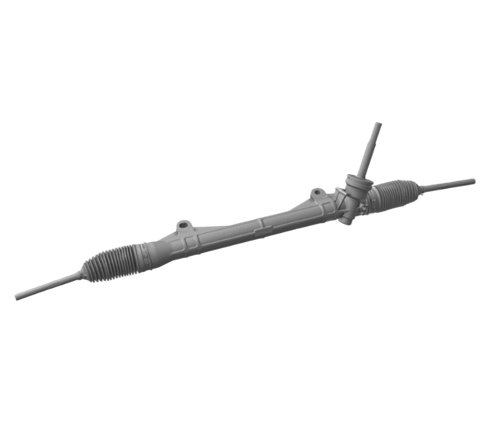

Mechanical steering rack • Combo

Colossal cleaning machine • Combo

Dutch Police mock crime scene • Combo • HD

Footprint • Combo • HD

Semi-trailer truck • Combo • HD

Pet hair dryer • Leo • HD

Divers’ helmet • Leo • HD

Body scan • Leo

Forensic mannequin at crime scene • Leo • HD

Crime scene hatchet • Leo • HD

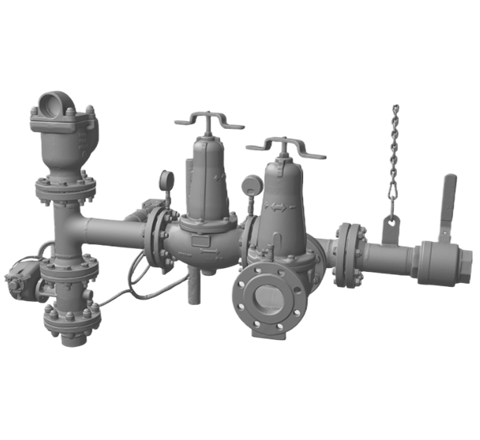

Pipe system • Combo

Air rescue helicopter • Combo

Smart car frame • Leo • HD

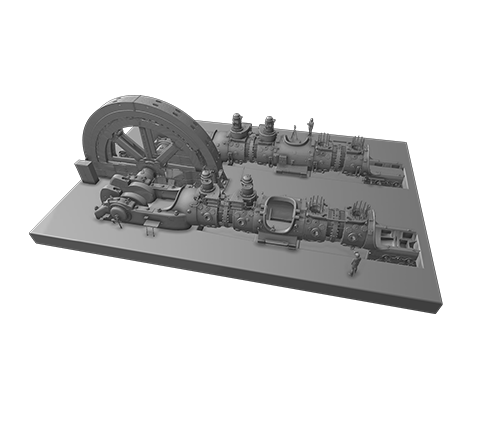

Blast furnace gas engine • Combo

Animal print accent chair • Leo

Suspension bracket • Leo

Axle shaft • Leo • HD

Goat skull • Leo • HD

Textured vase • Leo

Patchwork chair • Leo • HD

Car engine • Leo • HD

BMW manifold • Leo • HD

Christmas Bear • Leo