Artec 3D scanners for manufacturing

From concept to actualization, Artec 3D scanners will transform your workflow across the entire manufacturing process.

3D scanning for manufacturing

Artec 3D scanners are industry-leading precision instruments that play crucial roles in a variety of processes in industrial design and manufacturing. From product development to manufacturing, our high-precision 3D scanning solutions cut the time and cost of capturing object data. Highly accurate scan data improves the reliability of processes, and seamless compatibility with a variety of widely used CAD and CAM programs allows you to deploy them in quality control, reverse engineering, and many more manufacturing-related use cases.

Benefits

An Artec scanner takes one second to capture up to 35 million points. A CMM needs hours to capture a few hundred.

Artec 3D scanners work without targets and are precise to fractions of a millimeter. Our desktop 3D scanner achieves accuracy as high as 10 microns.

Artec scanners are designed to be intuitive, versatile, and easy to use. You’ll be confidently scanning in under 2 hours!

Just by using Artec scanners, an international manufacturer and distributor of construction machine spare parts saves 85 percent in time and cost.

Applications

Rapid prototyping

Cut down on the time it takes to get from design to production using precise, high-resolution 3D models of prototypes to quickly and easily test your designs.

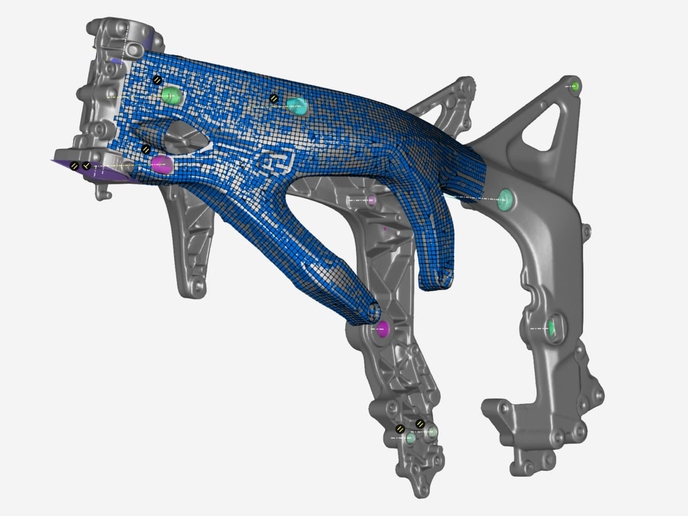

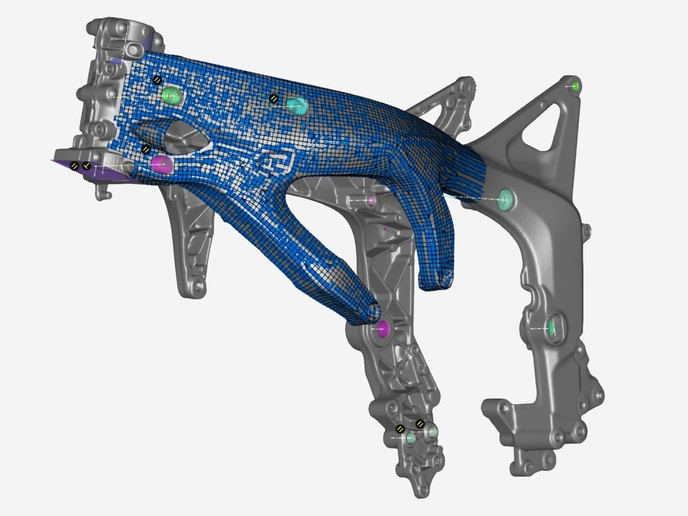

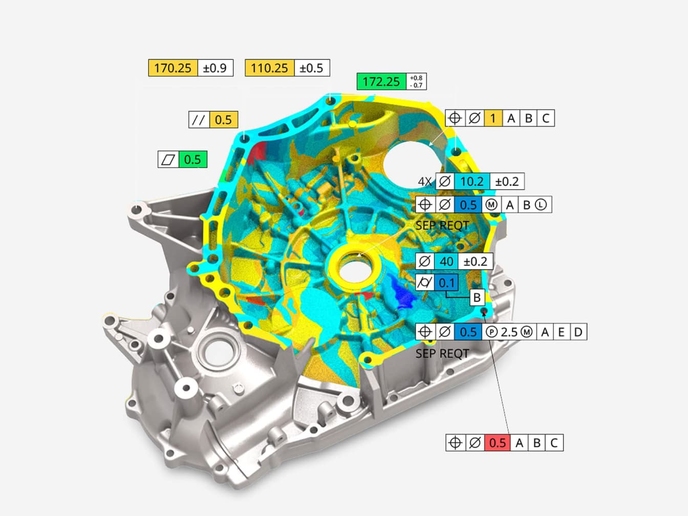

Inspection and quality control

Reduce time-to-market by optimizing the quality control process. Get accurate 3D models in minutes, which you can compare to CAD designs.

Reverse engineering

Fabricate parts with missing documentation, integrate existing products into your design process, or recreate legacy designs easily without needing to take manual measurements.

Drastically reduce lead times

By using 3D scanning methods, companies have reported reducing lead times in production processes like packaging by as much as 20 times.

Additive manufacturing

Go beyond conventional manufacturing techniques and use the flexibility of additive manufacturing to bring previously impossible design concepts to life.

Success story

A Swiss food-packaging manufacturer reports up to 2000 percent processing time improvements, and subsequent cost savings when creating new packaging.

Improvement in the processing time for Swiss chocolate bunny packaging. Artec Space Spider cut the time from 20 hours to just one.

"It's fun to see how quickly complicated shapes can find their way from hand to screen. Being able to use a 3D scanner in house is an immense time advantage. The simple usability is a winning factor — we are very satisfied with the results."

In the media

More on 3D scanning for manufacturing

All manufacturing related case studies, 3D models, and videos in one place

Artec 3D hardware

Artec has a line-up of scanners that can capture all kinds of objects, from entire airplanes to small nuts and bolts, and all without targets. Portability, ease of use, and performance are front and center, so scanning tricky surfaces or objects in difficult locations is fair game.

User-friendly portable laser 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Built for scanning in advanced resolution and perfect color, this target-free 3D industrial scanner captures complex geometry and sharp edges.

Our bestselling structured-light 3D scanner. Fast, versatile, and accurate.

Powerful long-range laser 3D scanner for precise capture of massive objects and scenes with remarkable speed and high accuracy.

A metrology-grade 5-micron accuracy desktop 3D scanner and automated, one-click solution.

Photogrammetry kit with 2-micron accuracy, metrology-grade precision, and high volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

What’s the next step?

Unparalleled efficiency gains in manufacturing workflows

Find out how the power of our scanners is helping manufacturers worldwide enhance their processes and optimize their workflows.

Slashing up to 75% off a foundry’s production time and cutting costs with Artec Eva

“The rate at which you can capture data is fantastic… Without a doubt Eva has saved our company money. We definitely promote it to customers as a valuable tool that will enable us to meet their castings’ requirements.”

Spare parts manufacturer in mining and construction uses Artec Eva for quality control, parts restoration, and repair

“Most of all, I like the scanning process. I also like the ability of Artec Eva to work on battery power, the convenience of scanning and processing in Artec Studio, and the accuracy of scanning.”

Artec Leo and Ray facilitate the safe removal, refabrication, and replacement of a damaged 15-meter vertical pipe on an offshore vessel in West Africa

“The combination of the handheld Artec Leo and the standalone unit Artec Ray made a very big difference. We managed to capture all the necessary details this way.”

Swiss food-packaging manufacturer cuts costs and time on chocolate bunnies packaging process from twenty to just one hour

“It's fun to see how quickly complicated shapes can find their way from hand to screen. Being able to use a 3D scanner in house is an immense time advantage. The simple usability is a winning factor — we are very satisfied with the results.”

3D scanners for your whole production process

Confidently capture objects of any size in different application scenarios, from small objects like tiny machine parts to huge construction implements, in a fraction of the time and effort.

Mobile and powerful handheld options

Take your scanner wherever you need it. Perfect for objects you can’t bring into your workshop. Compact, ergonomic designs enable you to scan different-sized objects even in difficult locations like tight spaces.

Solutions for high-accuracy measurements

Artec 3D scanning solutions all offer high-end accuracy, incredible speed, and excellent data quality.

Which 3D scanner will work best for you?

The Artec 3D scanner line-up has solutions for very different usage scenarios, object sizes, and manufacturing processes, and the flexibility to combine the strengths of different scanners to achieve even more.

User-friendly portable laser 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Built for scanning in advanced resolution and perfect color, this target-free 3D industrial scanner captures complex geometry and sharp edges.

Our bestselling structured-light 3D scanner. Fast, versatile, and accurate.

Powerful long-range laser 3D scanner for precise capture of massive objects and scenes with remarkable speed and high accuracy.

A metrology-grade 5-micron accuracy desktop 3D scanner and automated, one-click solution.

Photogrammetry kit with 2-micron accuracy, metrology-grade precision, and high volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

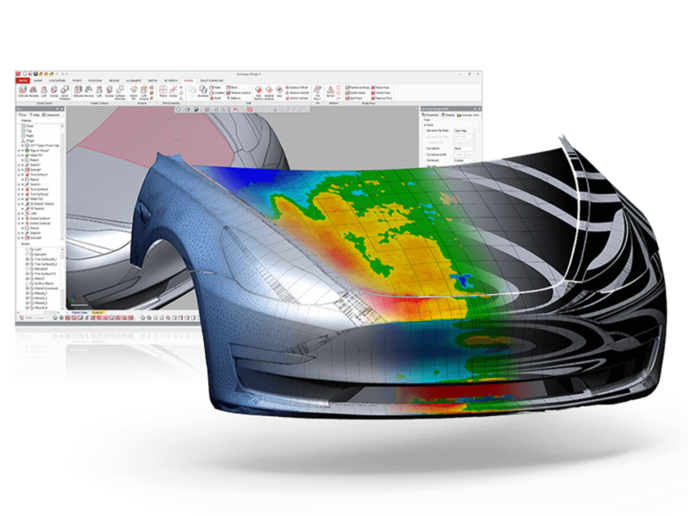

Seamless data capture and processing

Artec Studio provides a user-focused platform to ensure you’re constantly getting the best out of your 3D scanners for your manufacturing needs.

Also accessible to you

3D scanning for inspection with Artec 3D and Geomagic Control X

Manufacturing scanner + software bundles

Get even more value with a scanner or scanner combination, Geomagic Design X, and one or more Artec Studio licenses in one combo that fits your workflow.

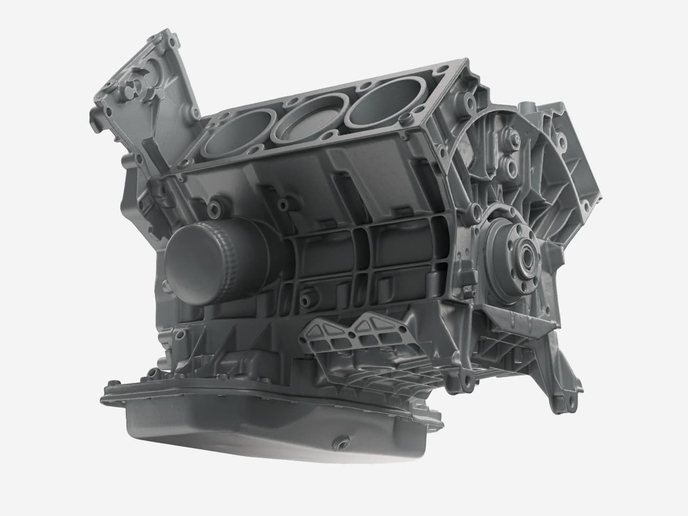

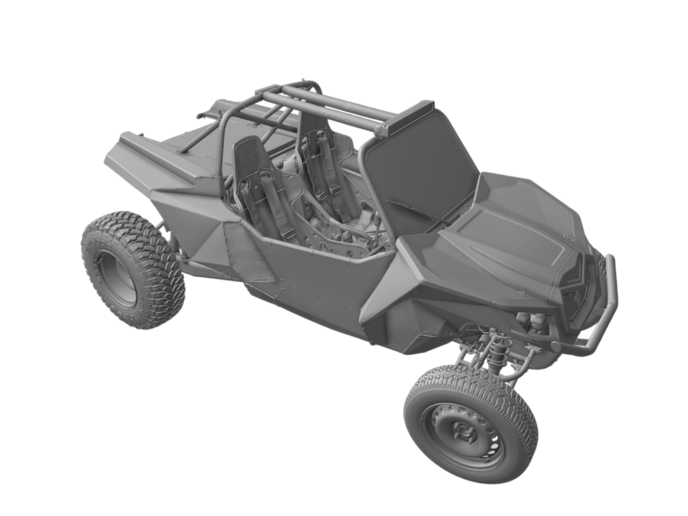

Remarkably precise 3D scans for CAD modeling

3D scan data and optimized workflows that take the complications out of the CAD modeling process. Take a look at some of the models our industry-leading 3D scanners have produced.