OBJ 3D models

Saucony Matrix sneaker • Spider II

Classic pocket watch • Spider II

Prop gun • Spider II

Incense lamp • Artec Studio

Knight’s helmet • Artec Studio

Fisherman statue • Artec Studio

Chinese Qilin statue • Artec Studio

Houseplant • Artec Studio

Universal screwdriver • Artec Studio

Snout beetle • Artec Studio

Demogorgon • Artec Studio

Church • Artec Studio

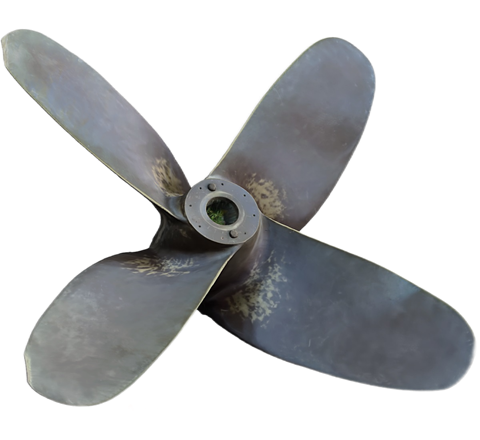

Ship’s propeller • Artec Studio

Elephant figurine • Spider II

Grasshopper • Artec Studio

Hydrant • Artec Studio

Car rim • Point

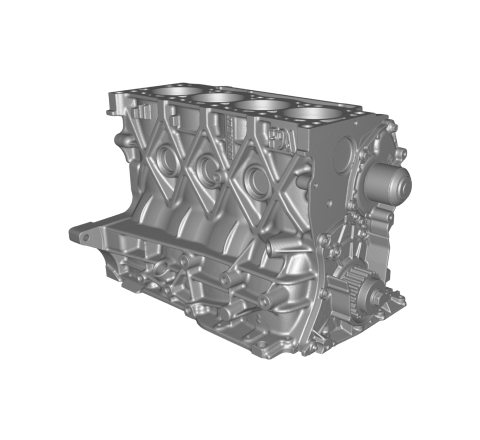

Four-cylinder engine • Point

Transmission • Point

Gray sneaker • Spider II

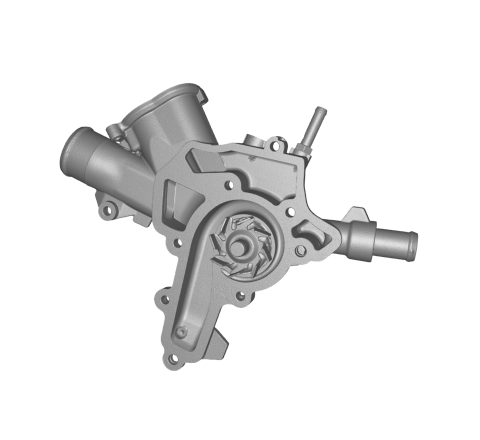

Water pump • Spider II

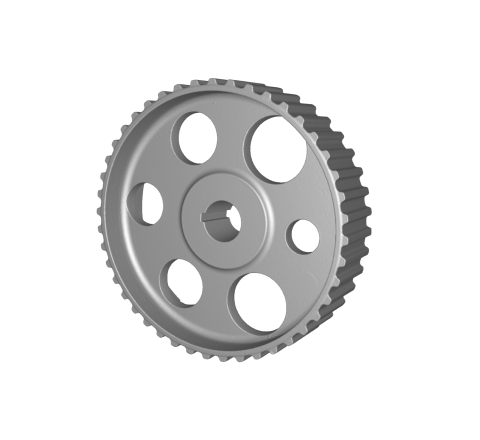

Cam gear • Point

Game controller • Spider II

EGR metal connection pipe • Micro II