Artec 3D scanners for QI solutions

Take your inspection process to the next level with fast 3D coordinate measuring technologies.

3D scanning for inspection

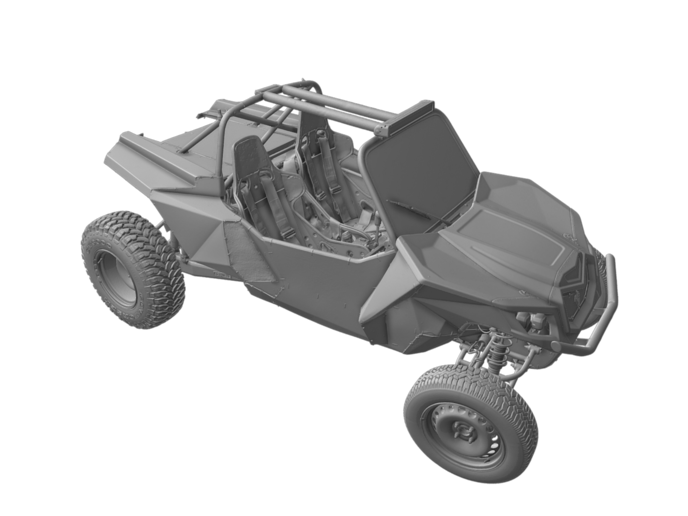

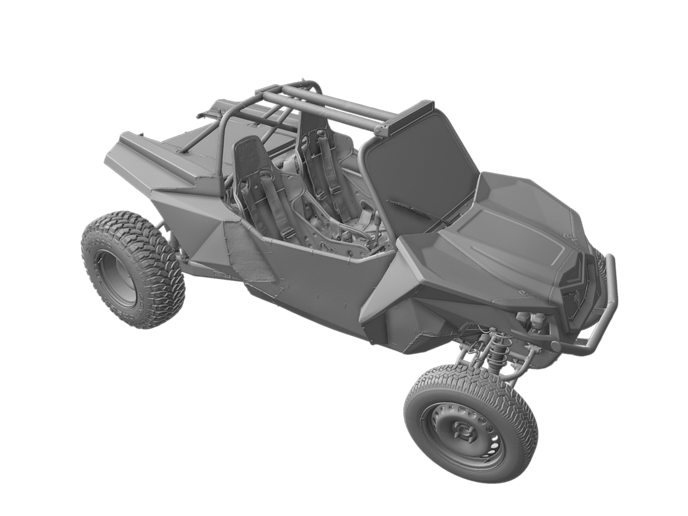

Engineers and metrology experts from top manufacturing companies that produce everything from automotive parts to medical equipment choose 3D coordinate measuring systems for their submillimeter accuracy, speed, and unbeatable ease of use – even when working with soft materials, objects with complex geometries, or freeform shapes.

Unlike traditional manual and contact-based measuring tools, which are often slow, time-consuming, and difficult to use, Artec scanners can with minimal training be quickly and efficiently used in design inspection, manufacturing control, delivery inspection, and more.

Benefits

Able to capture millions of points per second, all Artec scanners are incomparably faster than any contact-based measurement tool.

Artec scanners require minimal training, so in less than 2 hours you'll be ready to begin scanning confidently!

From Micro II to Ray II, all our scanners are non-contact, which translates to zero damage or deformation risk to any part you need to measure.

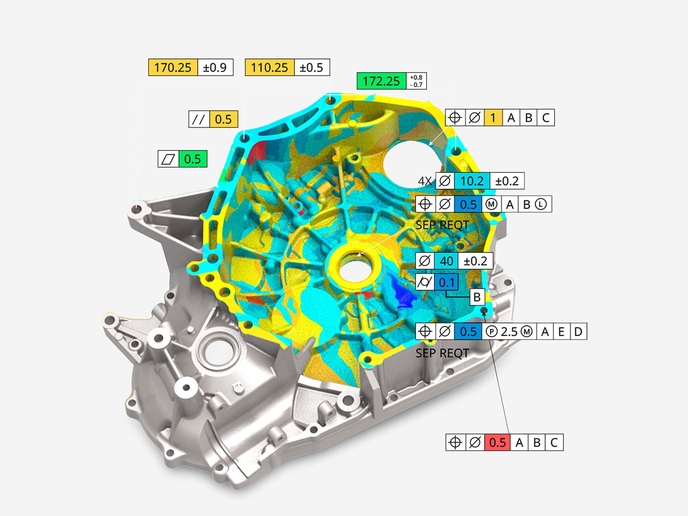

Precise, metrology-grade 3D scans at up to 2 microns’ accuracy.

Applications

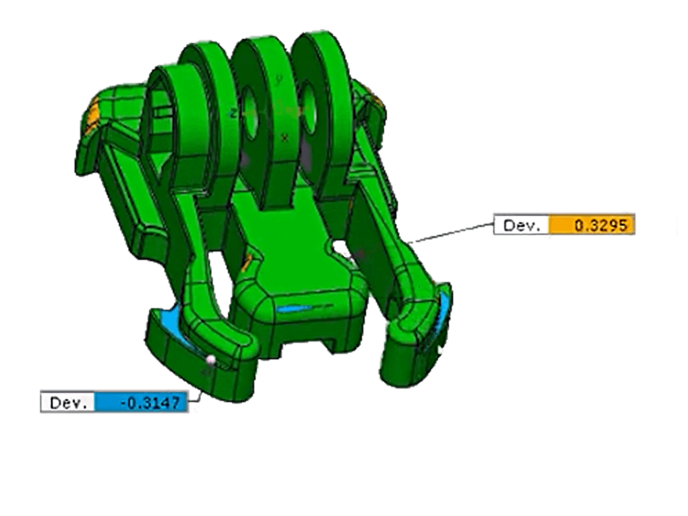

Machined parts inspection

With Artec's easy-to-use scanners, you are assured of the accuracy and precision of every part you manufacture.

Parts assembly management

Streamline and speed up your assembly process with a simplified QI plan.

Inspection of any part

Ensure each part – from huge to tiny – is measured and inspected anywhere you need, from the assembly line to the factory floor.

Medical device manufacturing

Easy-to-use inspection for medical equipment, where precision is key and accuracy is essential.

Quality customized tools

Keep every tool and its associated parts fully inspected for accuracy and precision with repeatable QI.

Injection molding inspection

Molds and the parts produced from them are guaranteed to be highly precise with Artec 3D scanners.

Plastics molding

Manufacture your molded plastic parts with the ease and efficiency 3D scanning provides.

Sheet metal stamping

Get it right the first time – and every time after – with high-precision inspection of sheet metal stamping.

Casting

Create and cast complex shapes with high resolution and accuracy while equipping yourself with ideal 3D measurement tools for evaluation.

Composite manufacturing & inspection

3D quality inspection allows you to build quickly and with confidence, even when combining dissimilar materials.

Additive manufacturing

Your 3D printed parts are ensured of precision when analyzed for QI in 3D.

Quality control

Remove all doubt from your industrial automation processes with high-level inspection through 3D scanning.

Success story

US jobbing foundry uses Artec Eva to slash up to 75% off production time, cut losses, and more.

reduction in manufacturing time with faster data capture and feedback on the production process.

“The rate at which you can capture data is fantastic. Without a doubt Eva has saved our company money and we definitely promote it to customers as a valuable tool that will enable us to meet their castings’ requirements.”

In the media

More on 3D scanning for inspection

All inspection related case studies, 3D models, and videos in one place

Artec 3D hardware

Accurate and easy-to-use, Artec 3D scanners quickly capture all the measurements you need in a matter of minutes, whatever the object – from tiny mechanical parts to large industrial tools.

User-friendly portable laser 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Built for industrial metrology, this lightweight, robust laser handheld scanner captures tricky surfaces with metrological accuracy and repeatability.

Built for scanning in advanced resolution and perfect color, this target-free 3D industrial scanner captures complex geometry and sharp edges.

Powerful long-range laser 3D scanner for precise capture of massive objects and scenes with remarkable speed and high accuracy.

Our bestselling structured-light 3D scanner. Fast, versatile, and accurate.

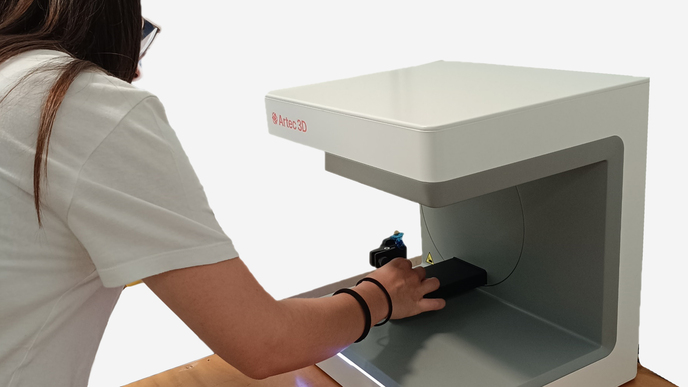

A metrology-grade 5-micron accuracy desktop 3D scanner and automated, one-click solution.

Photogrammetry kit with 2-micron accuracy, metrology-grade precision, and high volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

What’s the next step?

Next-level solutions when 3D and QI meet

Learn more about how 3D scanning has created quality inspection solutions at the highest level in various fields – the start of many a great story.

Finnish manufacturing company uses Artec Eva for quality inspection and ensuring repeatable accuracy

“Using Eva for quality control allows you to guarantee high quality of the delivered products, as well as to minimize logistic costs that would’ve been incurred when returning large equipment.”

Paris hospital uses Artec Space Spider for producing and inspecting medical supplies for doctors and patients since the beginning of the Covid-19 pandemic

“This is something we wouldn’t normally be able to do – we were creating a brand new framework for the purpose of printing medical supplies. The operation needed to be a big one, and one that worked accurately and quickly.”

US jobbing foundry uses Artec Eva to slash up to 75% off production time, cut losses, and more.

reduction in manufacturing time with faster data capture and feedback on the production process.

“The rate at which you can capture data is fantastic. Without a doubt Eva has saved our company money and we definitely promote it to customers as a valuable tool that will enable us to meet their castings’ requirements.”

More case studies

The accuracy you need is in your hands

Or on your desktop. Or in your workspace. When it comes to QI, accuracy is paramount. Here’s how 3D scanning provides the best solutions in your industry.

Accurate handheld measuring solutions

Artec handheld 3D measuring tools are extremely versatile. They can be used for quickly inspecting a wide variety of parts of different sizes and taken to a vast range of environments – this is especially useful when the object cannot be easily moved to an inspection lab.

Your best 3D scanning solution

Find the scanner that suits your needs best, whether you’re inspecting tiny parts or large machines.

User-friendly portable laser 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Built for industrial metrology, this lightweight, robust laser handheld scanner captures tricky surfaces with metrological accuracy and repeatability.

Built for scanning in advanced resolution and perfect color, this target-free 3D industrial scanner captures complex geometry and sharp edges.

Powerful long-range laser 3D scanner for precise capture of massive objects and scenes with remarkable speed and high accuracy.

Our bestselling structured-light 3D scanner. Fast, versatile, and accurate.

A metrology-grade 5-micron accuracy desktop 3D scanner and automated, one-click solution.

Photogrammetry kit with 2-micron accuracy, metrology-grade precision, and high volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

The right software for the best results

Get the best results from your scanner with software that perfectly matches your hardware, allowing full integration for optimal data capture.

Also accessible to you

Scanner & software bundles

With a software and scanner bundle, you have access to one (or more!) Artec Studio licenses and a license for Geomagic Control X. This special price provides you with all you need for QI.

Shine the spotlight on your object

Capture data from your object and examine it on your screen, in 3D, in as close a form as possible to the original object.