Restoring an iconic Dutch windmill with Artec 3D scanning & AI Photogrammetry

Challenge: Digitizing an entire windmill inside and out so that a Dutch infrastructure renovation specialist could carry out planned restoration works in challenging capture conditions.

Solution: Artec Leo, Artec Ray II, AI Photogrammetry, Artec Studio, DJI drone

Result: A full 3D model, including both the windmill’s outer structure and internal mechanisms, captured with sufficient accuracy for measurement and potentially reverse engineering spares.

Why Artec 3D?: Long-range LiDAR Ray II scans can be combined with AI Photogrammetry data to create complete 3D models of massive objects where accessibility is limited. The wireless, high-speed Leo can then be deployed to pick up fine details. Resulting digital twins feature incredible fidelity where it matters, while remaining lightweight and easy to export.

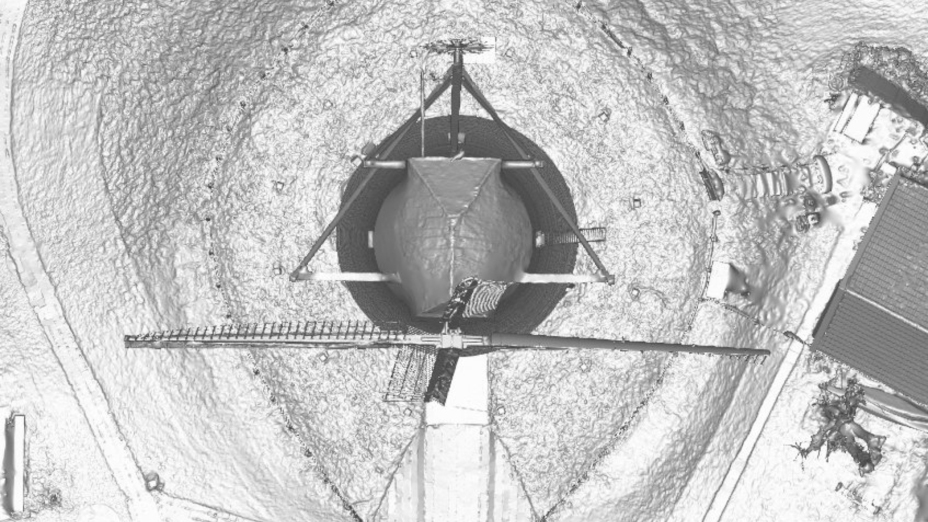

4C’s final 3D model of the Roelofarendsveen windmill. Image courtesy of 4C

Precision is absolutely vital in the world of architecture, especially when it comes to renovating historic buildings and other treasured heritage sites that need to be handled with great care.

Common infrastructure “lifting” processes like elevation, extension, reinforcement, or face-lifting can cause weakened, brittle, and irregular structures to collapse if not carried out properly. That’s why engineers survey such sites to weigh up any potential risks before work begins.

Generally, this process revolves around terrestrial laser or LiDAR scanning. However, many devices are limited to geometry (non-color) capture. They also tend to deliver data-heavy point clouds rather than meshes, making them difficult to work with in third-party software. And the biggest issue of all? Line-of-sight measurement, which limits capture to what they can see.

If you were to create a 3D model of a small everyday object, this wouldn’t be a problem. But in the world of large-scale infrastructure capture, scanning lofty, out-of-reach surfaces is a real necessity – working with incomplete digital twins can lead to costly project errors.

Facing this exact issue, a Dutch renovation expert reached out to 4C Creative CAD CAM Consultants (4C), looking for a solution capable of capturing the interior and exterior of a windmill in 1:1 scale to prepare for further renovation. The solution? Digitizing its exterior with the LiDAR Artec Ray II, interior using Ray II and the cable-free Artec Leo, and its roof by feeding drone data into Artec Studio’s AI Photogrammetry algorithm.

The windmill’s roof, digitally reconstructed with AI Photogrammetry. Image courtesy of 4C

Capturing a windmill from all angles

Asked to help a client renovate one of the Netherlands’ historic windmills in-between Amsterdam and The Hague, the 4C team arrived on-site on a chilly morning in early 2025.

To capture the building’s exterior, they began by deploying Artec Ray II. With a range of up to 130 meters, the tripod-mounted device can easily be set up and left to scan entire scenes, while its Visual Inertial System lends it real-time tracking capabilities. In this case, Ray II delivered a highly detailed scan of the mill’s blade and brick exterior, but the roof was still missing.

That prompted 4C’s owner Edwin Rappard to deploy a DJI drone. AI Photogrammetry’s video compatibility made roof capture incredibly easy. Even as a drone-flying amateur, Rappard found it possible to achieve brilliant results by simply flying around the structure and hitting Record.

However, the team’s dataset still didn’t account for the inside of the windmill, which is home to an intricate system of cogs that drive the mill’s rotary system. Digitizing this meant deploying Artec Leo, a cable-free handheld that captures 35 million data pts/second. Here, Leo allowed them to climb into this cold, cramped space and scan everything with speed and accuracy.

Where more space was available inside the mill, the team also used Ray II to collect data at top-speed, knowing that data from different scanners can easily be combined in Artec Studio. According to Bart Wever, the 4C 3D scanning specialist who climbed inside the windmill, Artec 3D scanning proved perfect for the job, capturing all the precision inspection data required.

4C’s final 3D model showing the Roelofarendsveen windmill’s interior. Image courtesy of 4C

“The biggest challenge was to align the two datasets of the inside and outside, because the mill only had very limited openings. You had a small front door and back door, so it was not easy to get scans from both inside and outside for correct alignment afterwards,” Wever explained. “But with the Ray II, we could do the job without a lot of issues. In the end, that was sufficient for building a perfectly aligned, complete 3D model.”

“We achieved great alignment without needing any checkerboards or markers. Ray II’s onboard VIS system worked perfectly. There were no challenges there!”

Merging datasets in Artec Studio

You’d think combining three very different datasets would be tricky, but Artec Studio streamlined the whole process. The software’s multi-resolution fusion algorithm allowed 4C’s team to create an incredibly detailed model using the highest-resolution data from each scan. Photogrammetry was then used to generate a roof mesh, which was merged with the more detailed dataset.

Interestingly, Wever found that using all the easy-to-use tools in Artec Studio creatively, he could separate captured data into cohesive parts and reunite these after import. This helped ensure that data wasn’t too dense for his PC to handle. Artec Studio’s scan decimation can also be used to a similar effect, reducing the polygon count to make the 3D model easier to handle and utilize.

4C’s windmill model in X-Ray mode inside Artec Studio. Image courtesy of 4C

Another advantage of the team’s approach is that it allowed photogrammetry data to be scaled to the size of Ray II’s scans, resulting in a true one-to-one model with vibrant lifelike textures.

Overall, combining datasets delivered hugely impressive detail capture. Everything from narrow blade panel gaps to individual gear teeth and the windmill’s three separate floors are clear to see. In fact, if this rotor system required maintenance, Wever reckons that data was captured so accurately it could be used to reverse engineer and manufacture end-use spares.

“With these types of buildings, one-millimeter tolerances are already considered quite high, making Leo more than sharp enough for capturing a 3D model and reproducing individual cogs,” explained Wever. “They’re also quite large – a giant cog wheel spins the entire structure. We’re not talking about tiny parts here. If it could fit, I’m convinced Ray II would’ve been enough.”

Further opportunities in architecture?

In the end, the 4C team captured sufficiently accurate data for their client’s windmill renovation purposes. But they’re not stopping there – they see significant potential for Artec 3D’s unique combination of 3D scanning and photogrammetry in the wider infrastructure space.

4C’s windmill model inside Artec Studio. Image courtesy of 4C

Rappard describes AI Photogrammetry as “the perfect addition to 3D scanning” and says “no other package on the market” can combine diverse 3D datasets quite like Artec Studio. Using complete, highly detailed 3D meshes rather than heavy point cloud data, he believes that architects and construction engineers will soon take surveying to new heights.

“Using Ray II together with a drone – and Leo, of course – is ideal for digitally preserving heritage sites, but it can also be useful in construction, a market where we still see a lot of potential for 3D scanning,” concluded Rappard. “When we first entered 3D scanning, we were like missionaries (spreading word of its benefits). Now it’s like a throwback. The technology’s become common in engineering, but in the building industry, it still has that wow factor!”

Clearly, traditional technologies still have a stranglehold on construction. However, with 3D scanning experts like 4C on the case, surely it’s only a matter of time before Artec’s diversified 3D data capture offering carves its own niche in the industry’s modernization.

Scanners behind the story

Try out the world's leading handheld 3D scanners.