Industrial 3D models

Smart car frame • Leo • HD

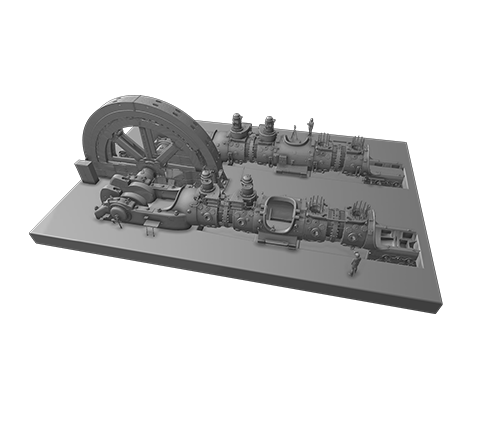

Blast furnace gas engine • Combo

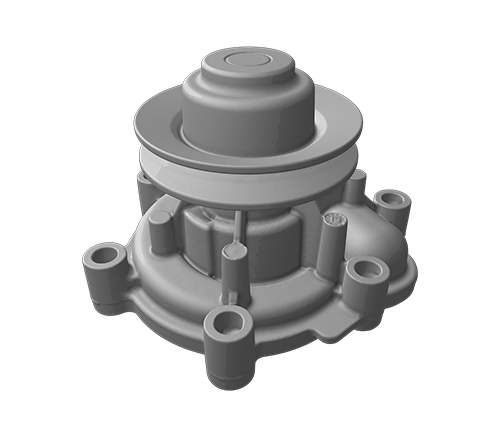

Automotive water pump • Space Spider

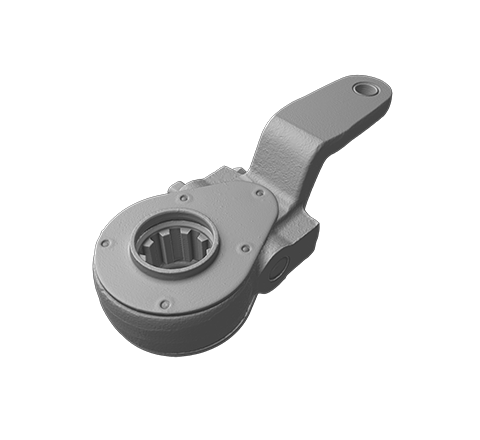

Adjusting lever • Space Spider

Suspension bracket • Leo

Axle shaft • Leo • HD

Car engine • Leo • HD

BMW manifold • Leo • HD

Buggy • Leo • HD

Bobcat skid-steer loader • Leo • HD

Snowmobile • Leo • HD

Motorcycle Crankcase • Space Spider

Motorcycle upper triple clamp • Space Spider

Mercedes-Benz CLK 430 Convertible • Leo • HD

Socket cap screw • Micro

Crankshaft • Combo

Crankshaft HD • Leo • HD

iPhone 4S SIM card tray • Micro

Fairing • Leo • HD

Crankcase • Leo • HD

Tripod • Eva • HD

Compound bow • Eva • HD

Clamp • Micro

Kayak • Leo