Industrial 3D models

Mechanical steering rack • Combo

Engine piston • Artec Studio

Universal screwdriver • Artec Studio

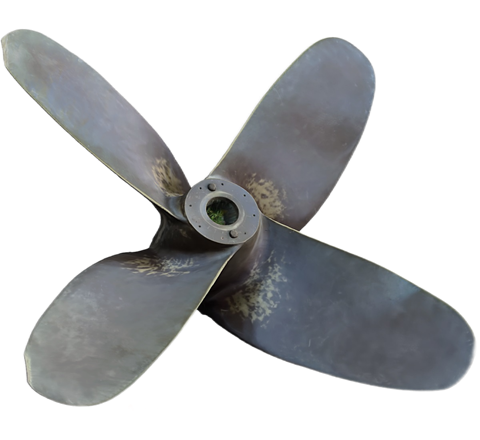

Ship’s propeller • Artec Studio

Hydrant • Artec Studio

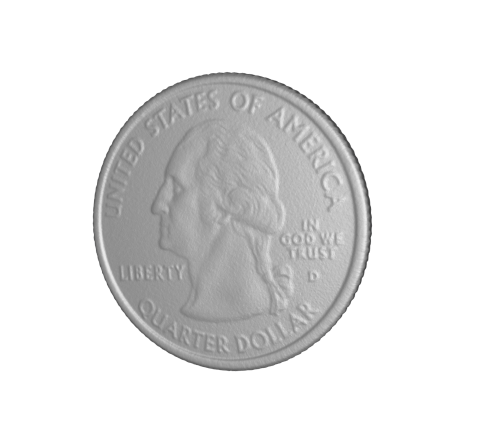

Quarter dollar • Spider II

Euro coin • Spider II

Car rim • Point

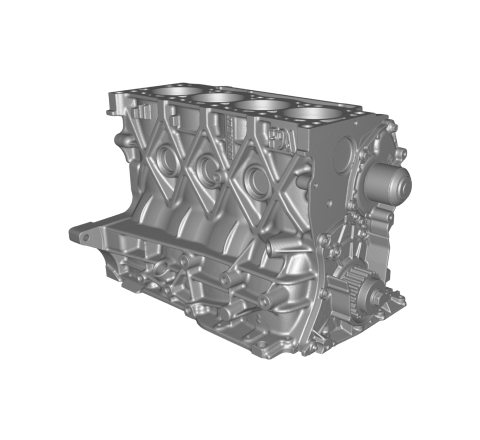

Four-cylinder engine • Point

Transmission • Point

Gray sneaker • Spider II

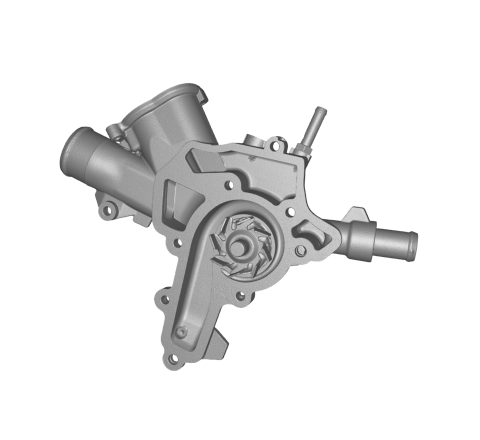

Water pump • Spider II

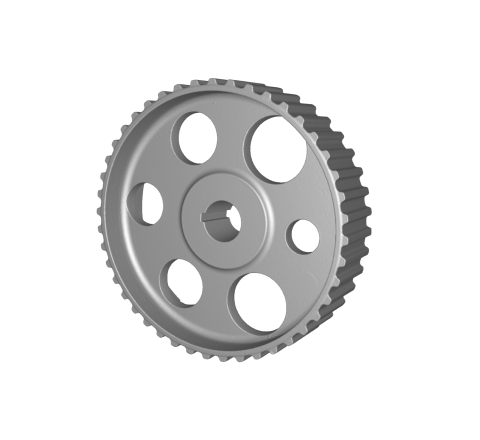

Cam gear • Point

Game controller • Spider II

EGR metal connection pipe • Micro II

Colossal cleaning machine • Combo

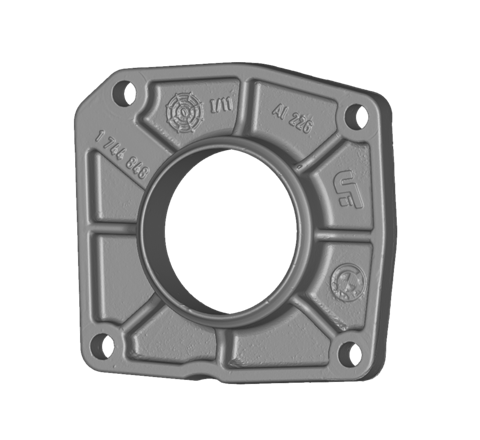

Industrial part • Micro II

Pipes • Ray II

Semi-trailer truck • Combo • HD

Pet hair dryer • Leo • HD

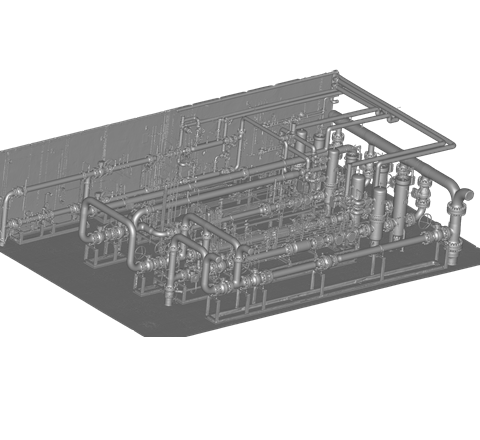

Pipe system • Combo

Air rescue helicopter • Combo

Smart car frame • Leo • HD

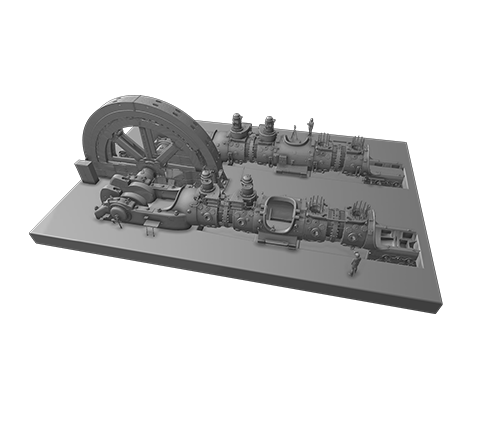

Blast furnace gas engine • Combo