Modernizing sailmaking with custom boat covers, made to measure using Artec Leo

Challenge: Transforming traditional sailmaking techniques into a modern, digitized, easier to carry out process that allows for greater design freedom and more efficient data processing.

Solution: Artec Leo, Artec Studio, Rhino 3D

Result: A streamlined workflow that only requires two site visits: one for measuring and another for installation. 3D scanning gives designers the full picture, so they can avoid costly errors. Going from scan to model takes mere hours in a completely digital environment.

Why Artec 3D?: Artec Leo is incredibly easy to pick up and start using, it’s also target-free – which is vital, as it would otherwise be impractical to scan up-to-40-foot boats. Artec Studio workflows automate scan data processing, while delivering faster, more repeatable results.

Zeilmakerij de Vries Maritiem is one of the largest sailmakers in the Netherlands. Founded in 1830, it’s also one of the oldest, with nearly 200 years of experience. Passed down through generations, this knowledge has made it a trusted service provider to boat owners across the country. But tradition needs to be balanced with modernization, especially in manufacturing.

Manual techniques like hand-lining and fitting with plastic foils have their place – and they certainly bring a sense of hand craftsmanship to the industry. But they’re also highly reliant on the individual user. This makes it increasingly difficult to pass skills down to the next generation, who are more at home in front of a PC than using traditional equipment.

Aiming to digitize its design processes, the company brought in Marko Vreeling, a kitesurfing aerospace engineer turned sailmaker, five years ago. Since then, he has overhauled the way it customizes many textile products, especially protective sprayhoods and covers. Initially, Vreeling tried integrating point-by-point Proliner technology, but it didn’t capture the full picture.

That’s why he reached out to Artec Ambassador 4C Creative CAD CAM Consultants, who demoed a whole range of handheld 3D scanners. The standout choice? Artec Leo. With no cables, onboard processing, and a built-in display for real-time feedback, the device is perfect for digitizing large objects at pace, while capturing complete datasets for product design.

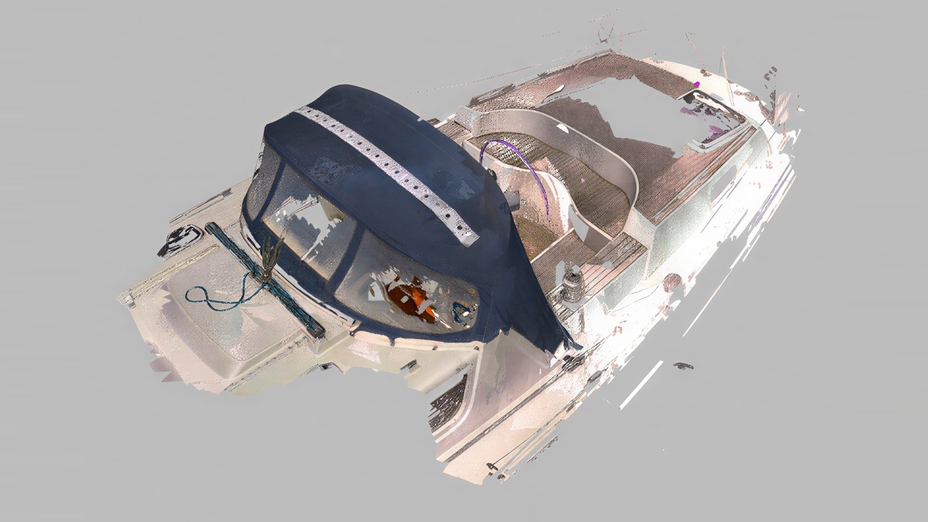

A boat 3D scan captured with Artec Leo. Image courtesy of Zeilmakerij de Vries Maritiem

Artec Leo: Ideal for maritime digitization

In theory, small vessels are sold in “models” just like cars. But in reality, no two boats are the same. Small manufacturing differences and customer requirements always change the dimensions of the required end product. So, it’s vital to measure boats before applying protective covers. During customization, context is similarly important, as failure to design around exterior features can cause manufacturing errors.

According to Vreeling, this was a particular issue with Proliner technology: “You don’t have the rest of your environment,” he said. “Only a line or a point, you have to imagine what the rest will be.” His previous approach involved making three trips to the client: one for measurement, another for sizing up, and a final visit for installation. With Artec Leo, he now skips step two entirely.

Using measurements captured with greater reliability, his colleagues are able to design frames in-house, manufacture via CNC bending, and head out for installation. Vreeling says the big difference here is contextual data capture and skill requirements – Leo guarantees results other solutions can’t, while its unique all-in-one functionality makes it incredibly easy to use.

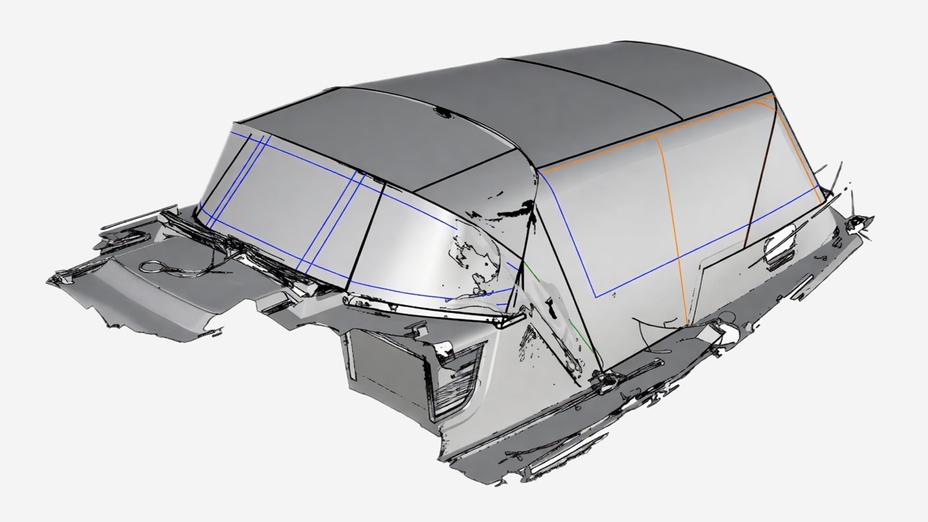

Measurement data based on the Artec Leo scans. Image courtesy of Zeilmakerij de Vries Maritiem

“The operator who uses the Proliner at our company is really good – and capable. He knows what to measure. If I send you or someone else, a newbie with that machine, it will definitely go wrong,” explained Vreeling. “But if I send you with a 3D scanner, it will definitely go right, because you’ll capture everything, and we can go through the data to measure whatever we need.”

Embracing Workflows in Artec Studio

Since Vreeling adopted Leo, the Artec Studio 3D data capture and processing software has received numerous updates. Having recently upgraded from AS16 to AS20, he’s noticed a big difference in algorithm speed and automation. Using Workflows, for example, the company is now able to establish presets that turn scans into detailed 3D meshes at the click of a button.

In Vreeling’s workflow, scans are registered, aligned, and fused before outlier removal is used to reduce noise, while mesh smoothing & healing apply polish, and simplification cuts the polygon count. This final step is particularly important for easing the load on Rhino 3D, where meshes are used as a basis for designing sprayhoods and covers, without needing to return to the site for manual fitting.

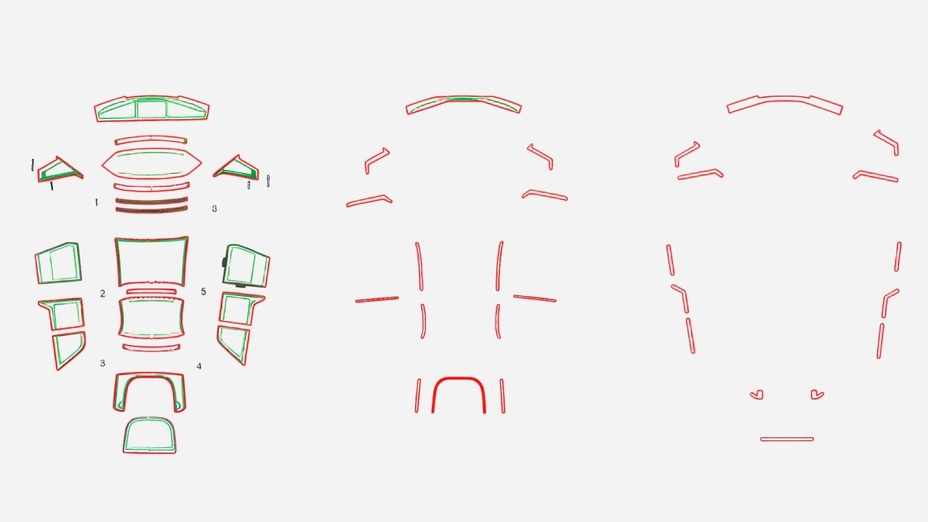

“In the past, we’d have to go back to the boat with plastic foils to make the sprayhood. Now, we can see completely how our product will be, and design at the office,” said Vreeling. “Afterwards, we ‘flatten’ the design, paste the parts together, and split them into material wicks. Finally, we implement stitching areas, air breeder holes, things like that, and send the design to a CNC pre-cutter.”

CNC cutting outlines for a custom boat cover. Image courtesy of Zeilmakerij de Vries Maritiem

Artec Leo is already Zeilmakerij de Vries Maritiem’s preferred method for creating steering wheel, table, helm, stock, and rudder covers that protect against adverse weather. In cases where boats are too small to climb inside, Leo is also measuring where it was previously impossible, and the device is so versatile, Vreeling can hang over the edge to capture the otherwise inaccessible.

Chasing further lead time gains

Asked whether the business would consider expanding into other areas of maritime maintenance, repair, and overhaul (MRO), Vreeling says it’s not their area of expertise. Instead, the focus remains on driving efficiency, something he links to further technological advances.

“I think that computers will go faster in the future, Artec Studio will keep getting better, and more cameras will become available,” concluded Vreeling. “So, I can imagine that within the next five or ten years, it will be the case that I don’t even need to go to the boat anymore. I can ask my customer to send me a scan captured with an iPhone, and I’ll be able to work with it.”

The final product: a custom sprayhood, designed with the help of Artec Leo. Image courtesy of Zeilmakerij de Vries Maritiem

With much of the industry sticking to traditional methods, Zeilmakerij de Vries Maritiem is fast becoming a digital pioneer. Combining Leo 3D scanning with time-tested techniques gives the company the versatility to tackle any sailmaking task. As an early adopter, it’s also well placed to continue innovating and bring bespoke boat accessories to sailors across the Netherlands.

Scanners behind the story

Try out the world's leading handheld 3D scanners.