Artec Leo takes a stellar shot at digitizing a 4.5-billion-year-old meteorite

Challenge: A Dutch observatory put a massive meteorite up for sale to secure funding for future projects. Before the transfer to its new owner, an auctioneer commissioned a high-quality 3D model of the meteorite for archival records and a 3D-printed physical replica for public display.

Solution: Artec Leo, Artec Studio, 3D printing

Result: A hyper-realistic digital twin that served three purposes: offering a high-fidelity archival record, an exhibit for interactive digital displays, and a precise model for 3D printing.

Why Artec: Artec Leo, with its fully untethered mobility and ability to render irregular surfaces, made it possible to capture the unusual object, even in bright outdoor light, with no option to reposition it.

Replicad’s founder Jaap Termeer 3D scanning the Gibeon meteorite outside his house. Image courtesy of Replicad

What would you do if a 240-kilogram iron rock, older than the Earth, landed outside your house? While you ponder the many exciting possibilities, Replicad engineer Jaap Termeer has created a super-realistic digital twin. Such a scanning scenario is not especially common, even for 3D professionals, so when Hessink Fine Art Auctioneers commissioned a high-resolution 3D scan for documenting the meteorite and creating a 3D-printed replica, Termeer became a part of a fascinating digitization story.

Largest iron meteorite ever auctioned, oldest ever digitized

The Gibeon meteorite is a unique iron meteorite that crashed onto Earth a few thousand years ago. Found in 1836 near the village of Gibeon in Namibia and brought to the Netherlands before export regulations were introduced, it is quite rare compared to other types of meteorites. Thanks to its iron-nickel alloy composition, containing significant amounts of cobalt and phosphorus, the Gibeon meteorite boasts striking Widmanstätten patterns (crystalline structures). They form when etched, making it popular among jewelry designers and collectors.

Originally the core of a shattered asteroid, this incredible celestial body traveled through space for millions of years, then fell to Earth. Pieces were scattered across a vast area, where they were initially used by the locals for tools and weapons. The large fragment scanned by Termeer is remarkable for how well the rock is preserved – even burn marks from its journey through the atmosphere are clearly visible, and there is practically no rust. However, the weight, size, and non-standard shape of the meteorite made it far from the easiest object to scan.

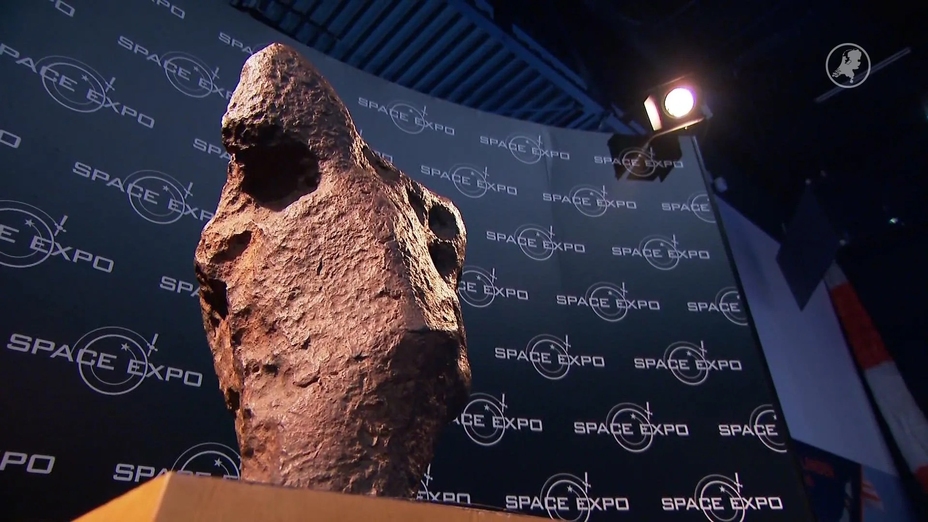

The Gibeon Meteorite on display at Space Expo. Image courtesy of Hart van Nederland

Mercurius Observatory in Dordrecht had owned the meteorite since 2004. In August 2025, the observatory put it up for auction, hoping to secure funding for its new planetarium and remain open for visitors. Making such choices is never easy, but the team prioritized building an interactive space and updating exhibitions to help their audience explore the universe in a modernized way.

Hessink Fine Art Auctioneers conducted the auction, and the meteorite went under the hammer at Space Expo, the country’s prominent space museum – with expectations incredibly high, as it was the largest iron meteorite ever auctioned. Even with eighteen bidders registered for the sale, including several internationals, the outcome was astronomical in every sense: an American buyer paid more than €1.7 million for the meteorite, with the purchase price topping €2 million (with fees included).

Before transferring the meteorite to its new owner, the auction house decided to create a high-fidelity 3D model for documentation and to 3D print a physical replica.

A portable 3D scanner for a large, irregular item

It was only logical that Replicad was tasked with this stellar mission. Founded by Jaap Termeer in 2015, Replicad has been offering 3D scanning and printing services for the business market ever since, establishing a solid reputation as an expert in all things 3D. Now, presented with the challenge of digitizing an asymmetrical object that was too heavy to lift and too precious to accidentally damage, Termeer needed the right tool for the job.

“So there it was, out on the sidewalk – a 4.5-billion-year-old iron rock with a pretty hefty price tag – waiting for me to scan it,” explained the engineer. “Because it weighs 240 kg, we had to use a small hoist to get the giant object into position, and we decided not to move the meteorite indoors.”

Jaap Termeer capturing the meteorite with Artec Leo. Image courtesy of Replicad

Having already applied Artec 3D solutions in numerous projects, Termeer opted for Artec Leo, a wireless powerhouse with an on-device screen, allowing users to see digital replicas being created in real time. Leo’s cable-free design and ability to render complex geometries in broad daylight made it the perfect choice for the outdoor scanning of a massive extraterrestrial object.

Even though the meteorite weighed far less than its original mass of 26 tons, it still couldn’t be flipped or rotated to access all areas. Instead, Termeer had to move around the rock to scan every part of its rough surface, with its many peculiar features, whether weathered fusion crust or tricky indentations.

Fortunately, this is exactly what Leo does best: capturing the object in high resolution while you simply walk around, targeting specific areas, with no cables getting in the way. By moving the scanner as if shooting a video, Termeer captured the meteorite from every angle, getting enough data to turn it into a high-end digital twin.

Termeer’s workflow makes all the difference

Not that you get to scan a meteorite every day, but the scanning process with Artec Leo, as demonstrated by Termeer, offers a great example of an efficient and reproducible digitization workflow for anything heavy, immobile, and full of intricate cavities. What was done here could easily be done when capturing monument fragments, stone sculptures, archaeological artifacts, or even pieces of machinery.

The key to a great 3D scan is always the combination of the right specialist, tools, and a well-planned setup. In this case, the 240-kilogram meteorite was positioned safely to ensure its stability throughout the scan. Bearing in mind the available space and lighting conditions, Termeer was able to adjust the scanner’s settings with ease. Leo’s real-time 3D preview allowed him to ensure full coverage while maintaining proper alignment, so that no sections were overlooked. In addition to the overall shape, details essential for the accuracy of the final digital twin, such as burn marks, for example, could be picked up with close-range scans.

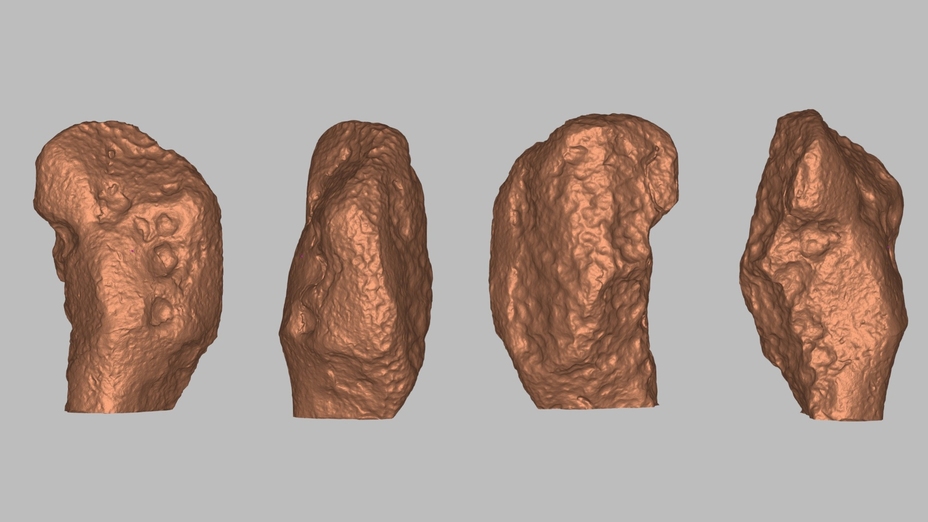

A 3D model of the Gibeon Meteorite. Image courtesy of Replicad

Once data acquisition was complete, scans could be transferred seamlessly to Termeer’s workstation and opened in Artec Studio for processing. In addition to global registration for precise alignment and the fusing of scans into a high-resolution mesh, the software offers a full range of refinement tools, from noise reduction to hole filling and texture mapping. Using this toolset, Termeer was able to recreate the object’s authentic appearance in his final digital twin.

Ultimately, his Gibeon meteorite model was of such a high quality that it could be used for archiving, digital display in an envisioned Dordrecht planetarium, and immediate 3D printing, for which the Dutch company Royal van der Most, a specialist in high-detail large-format 3D printing, was commissioned.

A physical replica of the meteorite being 3D-printed and displayed. Image courtesy of Royal van der Most

A digital meteorite and its earthly mission

What makes this scanning story particularly inspiring is the passion behind it. Scanning an extraterrestrial rock older than the Earth is already a one-of-a-kind experience, but documenting the largest iron meteorite ever auctioned is a historic moment for 3D digitization. Both the resulting model and its 3D-printed twin not only preserve scientific heritage that deserves to be captured in all its glory, they serve an important purpose: keeping an observatory open.

Digitizing something this old and magnificent also opens the door to many meaningful applications, from classrooms and museums to research labs and space stations. Digital twins like the one of the Gibeon Meteorite are indispensable for hands-on learning, interactive displays, and extending access to rare artifacts.

More broadly, this project is yet another illustration of how digital twins can revolutionize science, outreach, and heritage preservation. A single 3D model is something that countless professionals can rely on in their everyday tasks. Jaap Termeer’s doorstep encounter with a 4.5-billion-year-old space traveler has helped create a lasting digital legacy, bringing the cosmos within reach of anyone, anywhere.

Scanners behind the story

Try out the world's leading handheld 3D scanners.