Hydraulic arm modified with Artec Leo + Ray II 3D scanning for long-range excavation

Challenge: Customizing large, complex industrial equipment for specific project needs – in this case, attaching a longer hydraulic arm to extend the machinery’s overall reach.

Solution: Artec Leo, Artec Ray II, Artec Studio

Result: A complete 3D model of the original machinery, captured with sufficient accuracy for measurement, reverse engineering, and modification to allow for excavation at scale.

Why Artec 3D?: While Leo picks up tiny intricate details, Ray II captures the wider picture. Together, these devices are a formidable combination, capable of digitizing large objects or entire areas at speed, with high-resolution feature capture where it counts.

Artec Leo & Ray II at the customer’s workshop. Image courtesy of 4C Creative CAD CAM Consultants

At the heart of every construction project around the world, there’s a handful of vehicles doing all the heavy lifting. Whether it be a digger, a tractor, or a crane, this machinery needs to be safe, efficient, and fit for purpose – and the latter can depend quite a lot on the project at hand.

It’s often possible to change tools mounted to the end of their robotic arms, making industrial equipment fairly adaptable. But in certain cases, where necessitated by obstacles, ground clearance, or environmental hazards, more extensive modifications are required.

That’s where 4C Creative CAD CAM Consultants comes in. Over the last 6-7 years, the Artec Ambassador has offered its services to an excavator in the Netherlands. 4C’s latest modification project saw it called out to digitize a 10-meter vehicle featuring a cabin with complex internals, an air filtration system, and a boom mounted to a rotating platform with Caterpillar tracks.

Artec Leo with an on-screen 3D scan of the vehicle’s Caterpillar tracks. Image courtesy of 4C

Traditionally, getting hold of CAD data for such a large, complex structure would require slow, methodical manual modeling. Introducing 3D scanning into the equation allowed 4C to capture the equipment in its current state for measurement later on. Better yet, pairing Artec Leo & Artec Ray II meant not having to compromise scale or accuracy, allowing for the best of both worlds.

Leo & Ray II: A match made in heaven

With a built-in display, battery, and processor, Leo is usually more than capable of capturing large objects by itself. In this case, Ray II was brought in to supplement the device’s versatile scanning capabilities with long-range data capture. Mounted high above the rest of the vehicle, its robotic arm was especially difficult to reach with Leo – but it was no problem for Ray II.

Another challenge was capturing underneath. Weighing several tons, the equipment sat just 80 cm above ground level, making it unsafe to scan from below. Removing Ray II’s tripod and positioning it on the floor proved the perfect solution. This allowed the vehicle’s underbelly to be quickly, easily captured from all angles without any unnecessary risks.

Artec Ray II alongside the customer’s hydraulic arm. Image courtesy of 4C Creative CAD CAM Consultants

To meet customer requirements, 4C’s were also asked to capture the machine’s staircase. This is where Leo & Ray II really shone, as company co-owner Rogier Rappard explains.

“They wanted to extend the vehicle’s stairs,” said Rappard. “The challenge here was capturing the geometry of the stairs and the handrails – you could easily lose tracking. Using Leo, it also would’ve meant aligning a lot of scans. Instead, we captured with Ray II from the side. Then we used Leo to focus on scanning the most important parts with high resolution and accuracy.”

Merging different datasets in one click

In 3D scanning, the power is often in the software. This is especially true of Artec Studio, which boasts a completely unique feature: Smart Fusion. Not only does it combine point clouds from long and short range 3D scans, it uses the highest resolution data available for peak results.

Those wanting to take full control over data processing can also align scans themselves. 4C aligned its scans based on geometric features and merged them using the software’s Sharp Fusion algorithm. Compared to other target-based workflows, Rappard says this is “much more efficient and less time-consuming,” while still delivering an outstanding level of precision.

Scan decimation came in very handy with this project. Capturing the entire vehicle with structured-light 3D scanning would’ve resulted in a huge file with around 50 GB of information. Decimating the final model to remove unneeded polygons reduced this figure to just 300 MB, making it much easier to send to third-party software for modification.

Artec Studio’s ability to share fully formed meshes also lends itself to intuitive filesharing. Zooming in on point clouds can cause distortion, making them tricky to measure. But Ray II point clouds can be sent directly as OBJs and STLs that are textured, polished, and ready to go – and with these meshes, it’s easy to use CAD primitives for perpendicular measurement.

According to Rappard, Artec Studio’s built-in tools unlock a range of other applications as well, including feature extraction for design referencing. In this particular project, collected data turned out to be critical to strength analysis, carried out via simulations designed to ensure modification durability.

Technology that leaves users “blown away”

From forensics to the defense industry, 4C continues to find new applications for Leo & Ray II, a unique proposition in 3D scanning. No other solution merges LiDAR and handheld structured-light 3D scans so seamlessly – and new adopters are often left stunned by the results.

“Every time that I visit clients, Artec Studio makes it so easy to demonstrate pinpoint alignment. You just find similar geometry between two scans and align it,” concluded Rappard. “They are always asking: ‘Is it possible to combine scans? How does that work?’ When I show how simple it is, they’re always blown away about what’s possible with the technology.”

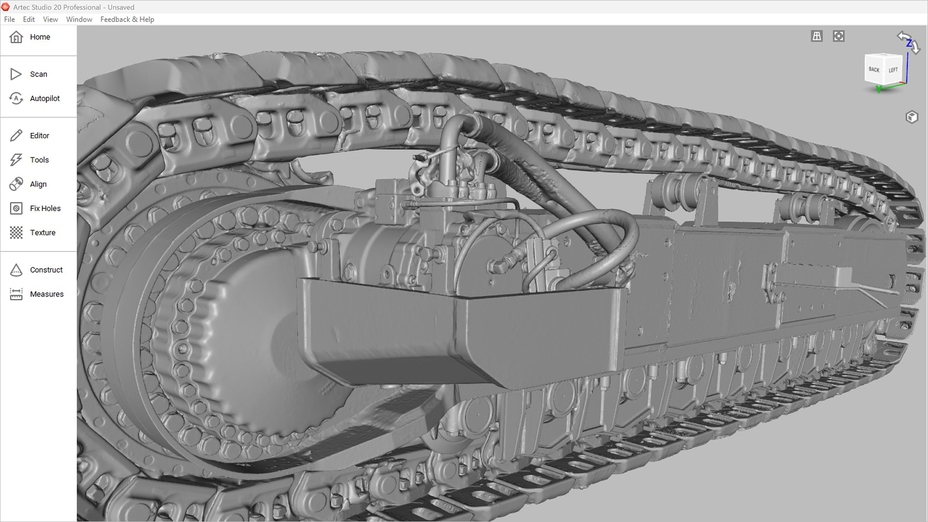

A 3D model of Caterpillar tracks captured with Artec Leo in Artec Studio. Image courtesy of 4C

Having the versatility to digitize large items in any environment also has real-world benefits. In another project, 4C was charged with capturing factory machinery. Without 3D scanning, it would’ve had to cease production for 2-3 days, so surfaces could be measured. Leo reduced overall downtime to just two hours – and adding Ray II makes this approach easy to scale.

Often, Leo & Ray II are deployable on their own. In the case of this vehicle, Leo could digitize the whole structure in high resolution. Ray II also captures large objects with ease. But together, they made it possible to generate a lightweight 3D model with accuracy where it matters. With this kind of versatility, it’s no wonder that the technology is taking off in industry and beyond.

Scanners behind the story

Try out the world's leading handheld 3D scanners.