Cases

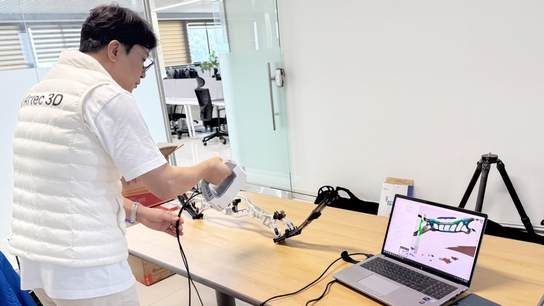

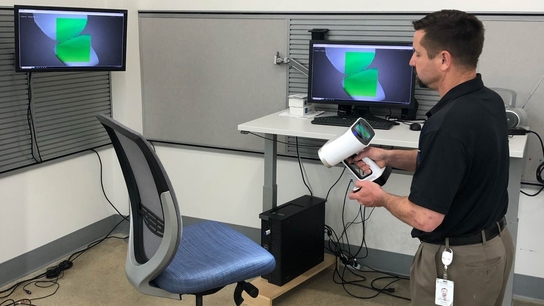

Artec 3D scanning applications in industrial design

With its precision, convenience, and speed, 3D scanning has become a must-have in many industrial design and manufacturing applications. The Artec lineup features powerful 3D scanners for industrial design, reverse engineering, quality control, and many other use cases. With the range of options available and seamless export into widely used CAD and CAM programs, you can be confident we have the best industrial 3D scanner for your needs.