Engine piston

This detailed 3D model of a piston head, measuring 10 cm in diameter and 10 cm in height, is a great example of how AI photogrammetry can approach a digitization challenge. The 3D replica of this engine component clearly displays all its critical elements, such as circular grooves and deep pin bores. The somewhat homogeneous surface is also impeccably preserved, showcasing the rougher casting finish on the interior and the smoother, machined surfaces of the ring lands. As you rotate the model, you can take a closer look at a hollow internal cavity with multiple apertures and milled channels. The combination of an almost featureless surface with thin cut-away contours, smaller circular recesses, and thread-like locking geometries all make the object not an easy target to capture - yet all of these are distinctly visible in a 3D model.

AI Photogrammetry made the model creation process much easier. First, we filmed a five-minute video of the piston head. From this video, in Artec Studio, we fully reconstructed the model in about two hours. The capture was done with a reference scale cross printed on an A4 sheet, we filmed the part flipped over, and added targets to break the symmetry of the object.

If you zoom in, flip, or rotate the model, you can notice even finer details, such as small alignment pin recesses, subtle inner surface texture variations, and sharp transitions between machined and cast areas. This model is well-suited for mechanical assembly visualization, reverse engineering workflows, precision tolerance analysis, and digital archiving of manufactured parts. Captured geometry results in clearly defined edges, smooth curvature transitions, and accurate hole diameters, providing a highly usable digital asset for manufacturing and industrial design.

License

Under Creative Commons license v4, attribution to Artec 3D and a link back to our website is all you need to use this 3D model for free.

Engine piston by Artec 3D

Available downloads

Embed 3D model on your website

Similar models

Universal screwdriver • Artec Studio

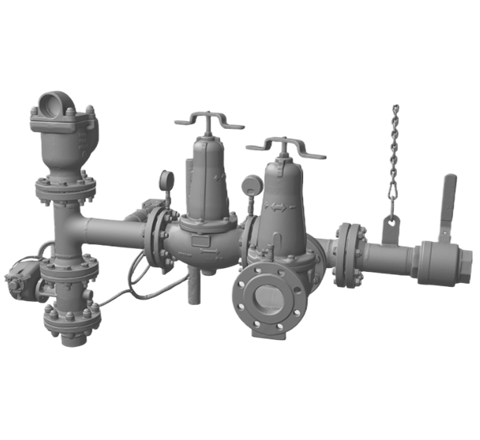

Pipeline segment • Ray II

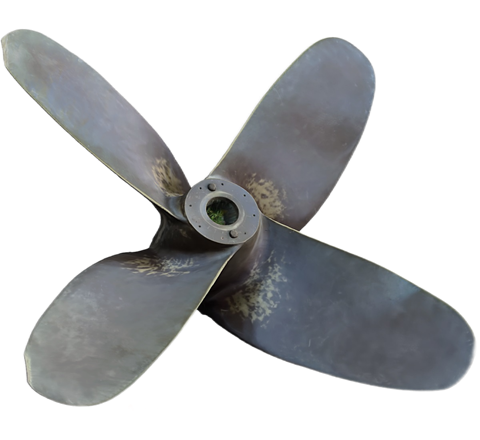

Ship’s propeller • Artec Studio

Hydrant • Artec Studio