Nature perfectly preserved: 3D scanning revolutionizes jewelry design

Challenge: Digitizing a hydrangea flower with precision—capturing delicate veins, petal textures, and organic curves for the Endless Summer jewelry collection. This required an alternative to manual techniques, which are time-consuming and struggle to capture fine details or achieve sufficient accuracy.

Solution: Artec Spider II, Artec Studio, ZBrush

Results: A faster, more efficient workflow, delivering richly detailed 3D models that seamlessly infuse natural beauty into jewelry design. With this new workflow, the user has shortened their design cycle by 50% – models can also be reused for future iteration and manufacturing.

Why Artec 3D: With exceptional hybrid tracking capabilities, Artec Spider II delivers ultra-high accuracy & resolution scans. The device is perfectly suited for capturing the intricate details of small objects, making it an ideal tool for jewelry design.

The finished pieces from the MONSECRET “Endless Summer” collection. Courtesy of MONSECRET

When natural inspiration meets technological barriers

In today’s era of rapidly evolving technologies, digitization has become an irreversible trend in the jewelry and broader craft industries. More and more designers are integrating 3D technology into their design workflow: transforming hand-drawn sketches into 3D models helps bridge the gap between creative vision and finished product, while the use of 3D printing opens up a straightforward pathway for producing precious metal prototypes.

In jewelry design, “paying tribute to nature” has never gone out of style. Yet the challenge remains: how can inspiration be transformed into a physical end-product? In traditional craftsmanship, designers often rely on hand-carving to replicate floral forms, but this process easily loses critical details such as the serrated edges of petals.

The finished pieces from the “Endless Summer” collection. Courtesy of MONSECRET

Even with 3D modeling software like Rhino or ZBrush, countless hours need to be spent observing real floral structures and manually reconstructing them. Photogrammetry offers some support, but it still struggles to capture subtle thickness variations of less than one millimeter between petals – precisely the kind of detail that brings natural depth and dimension to life.

Aiming to overcome these obstacles, emerging Chinese design brand MONSECRET set out to create a series of bracelets, necklaces, and hair accessories inspired by the Endless Summer hydrangea. Their overall ambition was to move beyond the subjective interpretations of petal curvature imposed by traditional lost-wax casting, instead authentically capturing the vitality of a blooming flower and its asymmetrical beauty.

Yet, to realize this vision, they’d need to overcome two long-standing industry pain points: precision and efficiency. Hydrangea petals are densely layered and intricately textured; without a deep understanding of botanical forms, modelers will struggle to reproduce the flower’s natural grace and vivid spirit. Even with significant time invested in manual modeling, achieving this standard of lifelike precision remains extremely difficult.

Hydrangea scanning on site. Courtesy of MONSECRET

Having witnessed Artec 3D’s success in fields like heritage preservation, the MONSECRET design team realized that 3D scanning technology could faithfully preserve the natural forms of flowers. This led the brand to partner with Ningbo FLD-TECH, Artec Gold Certified Partner in China. The handheld scanner Artec Spider II, their recommended solution, ultimately became the key to unlocking this digital design revolution.

Transforming fleeting blossoms into timeless beauty

With hydrangeas coming in many varieties, the team sought to showcase their vitality across different stages of bloom from budding to full blossom. This provided designers with a broader range of references, preventing design homogenization caused by reliance on a single model. Using Artec Spider II, they scanned hydrangeas of different species and growth stages from multiple angles, seamlessly going from “nature’s harvest” to a 1:1 digital replica.

The 3D scanning of a hydrangea flower with Artec Spider II. Courtesy of MONSECRET

Specially designed for capturing fine object details, the scanner seemed tailor-made for hydrangeas: its ultra-high resolution of 0.05 mm could reproduce the subtlest petal textures and curves. Its hybrid tracking technology, combining optical targets with geometric feature recognition, eliminated the need to apply markers to fragile petals. Even when flowers swayed slightly due to environmental vibrations, the scanner locked onto their position right away, preventing data distortion.

According to one technician: “Artec Spider II offers incredibly high resolution and outstanding hybrid tracking; no other scanner could achieve this level of performance.”

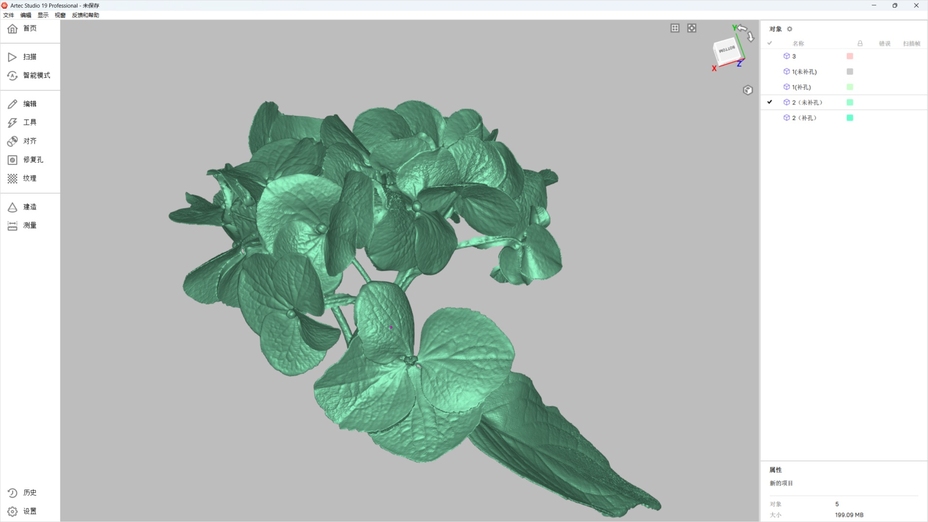

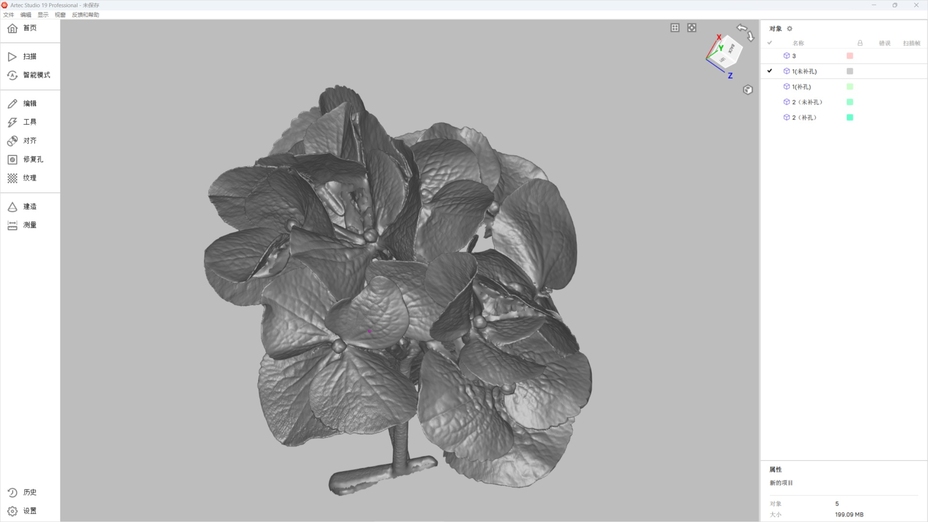

3D model of a hydrangea in Artec Studio. Courtesy of Ningbo FLD-TECH

Given that hydrangea petals are so thin and layered, capture could easily have resulted in broken geometry due to occlusion. To address this, the team carefully trimmed the bouquets and experimented with different arrangements during scanning. Leveraging real-time previews inside the Artec Studio software, they were able to monitor scan quality instantly and rescan any missing areas on the spot, avoiding the need for extensive post-modeling repairs. Resulting 3D models could also be exported from Artec Studio in OBJ, STL, FBX, and other formats, ensuring seamless compatibility with design software such as ZBrush and Blender.

3D model of a hydrangea in Artec Studio. Courtesy of Ningbo FLD-TECH

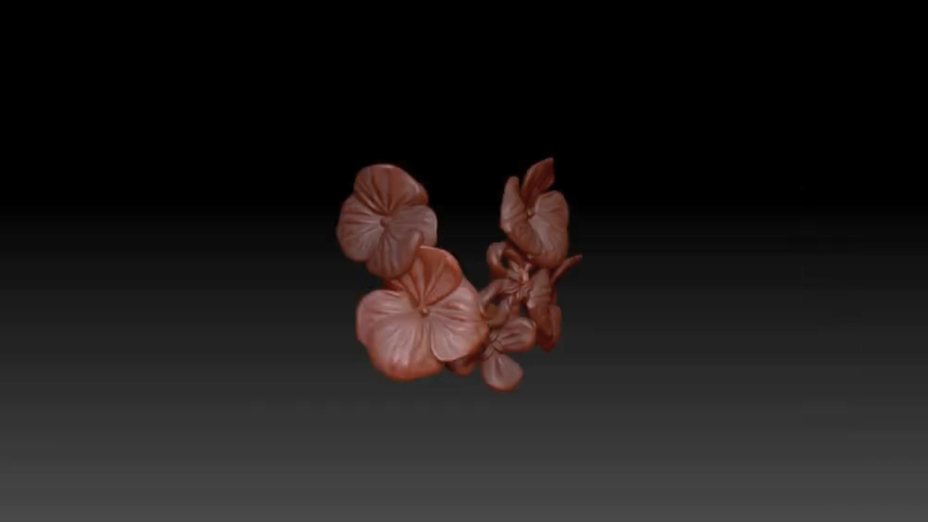

After aligning and merging scan data in Artec Studio, designers imported the refined 3D meshes into ZBrush for artistic processing. Individual petals were extracted as modular elements and assembled into bases for rings, necklaces, and hair accessories.

Through shape sculpting and topology reconstruction, surface smoothness was enhanced, and petal folds were added, allowing flower clusters to retain their natural rhythm while achieving a more three-dimensional bloom. A single hydrangea eventually gave rise to over a dozen distinct forms, adaptable to various wearing scenarios. Compared to manual modeling, which once took several weeks, their new design process was an impressive 50% faster. Better yet, every curve and texture now embodies the authentic vitality of the Endless Summer hydrangea.

Designers sculpt in ZBrush after Artec Studio processing. Courtesy of MONSECRET

“From selecting fresh flowers at the market to 3D scanning with an Artec scanner, building base meshes in Artec Studio, performing post-processing repairs, and then artistic refinement and metal casting, it took a total of 25 days,” explained the designers. “Normally, the entire process would take about a month.”

“Using 3D scanning technology, we saved one week,” they continued. “3D scanning also helped us reduce repetitive work. We could deform and modify the base models, making later adjustments much more flexible. The scanner faithfully captured the hydrangea’s natural details, preserving the organic curves and asymmetrical beauty of the blooms. This allowed us to enhance the uniqueness of our product designs.”

Redefining the fashion design ecosystem

When transforming these digital hydrangea models into physical jewelry, 3D scanning’s impact extended far beyond the creation of a single piece. The technology allowed natural inspiration to truly take root in jewelry design. A ginkgo leaf could become the framework for symmetrical earrings, and pinecone scales, once flipped and replicated, could form layered necklace pendants.

Even more remarkably, captured scan data supported scaling, twisting, mirroring, and other manipulations, allowing a single plant to inspire countless variations, each curve still carrying the breath of nature. In doing so, 3D scanning has not only helped realize the designers’ vision of “wearing nature” but opened up unprecedented creative possibilities for the fashion industry.

Final hairpin from the “Endless Summer” collection. Courtesy of MONSECRET

For brands, the adoption of 3D scanning technology brings significant advantages. It not only infuses the beauty of nature into jewelry design, enhancing brand uniqueness, but also dramatically shortens the production cycle for custom jewelry, effectively reducing trial-and-error costs. Processes that once took several weeks with traditional craftsmanship, from scanning a flower to delivering a finished model, can now be completed in just a few days.

Moreover, 3D-scanned models are highly versatile and easily used for subsequent design iterations. Designers can quickly optimize details in a virtual environment, enhancing both flexibility and creativity. 3D scanning is no longer just a tool; it has become a core engine that drives efficient brand growth and sparks design innovation, giving brands a clear advantage in a competitive market.

The finished pieces from the “Endless Summer” collection. Courtesy of MONSECRET

Looking ahead, the adoption of 3D scanning technology is set to accelerate. With declining costs and integration with AI algorithms, it is poised to become the industry standard, enabling more brands to seamlessly connect natural inspiration with digital fabrication at a lower threshold. In fashion design, scanned lace or embroidered fabrics can be used for 3D pattern-making and virtual fitting.

When combined with AR/VR in fashion-tech, it allows for the creation of “digital twin” jewelry, expanding consumer experiences into the metaverse. 3D scanning is breaking creative boundaries in traditional fashion, becoming a new “brush” in designers’ hands, performing magic across an ever-growing range of applications and leading the industry into a new era.

As 3D scanning and fashion design continue to converge, the future may see every designer carrying a scanner, transforming a flower or a single leaf on a street corner into tangible works of fashion art. The digital hydrangea of Endless Summer is only the beginning of this revolution.

Scanners behind the story

Try out the world's leading handheld 3D scanners.