BIMとは?

ビルディング・インフォメーション・モデリング(BIM)は、建設業界における建設現場管理の業界標準であり、プロジェクトのライフサイクル全体にわたる情報の取得、処理、保存に対応しています。LiDARやフォトグラメトリなどの3D技術が市場シェアを拡大しているにもかかわらず、これらはBIMエコシステムとは別のものとして分類されることが多々あります。本記事では、これらのソリューションが最適に適用されるケースと、業界をどのように前進させているかについて見ていきます。

BIMとは?

BIMは単に業界特有の3Dモデリングではなく、データ取得と処理のワークフロー全体に対応するものです。建物管理に関わるあらゆる作業(初期設計から解体まで)は、データの可視化・共有・分析を中心に展開されます。そのため、建築家やエンジニア、請負業者がBIMの概念をしっかりと理解することが不可欠となります。

それへの理解をより簡単にするためには、BIMの基礎を個別に調べるのがおそらく最善でしょう。

プロセス:本質的に、BIMはデジタルツールと協働的なワークフローを使用して、プロジェクトのライフサイクル全体にわたり建築情報を作成・管理する作業を含みます。これには、モデリングや製図、ISO規格への準拠など、数々のステップが含まれます。上記のすべては、部門間の統合とプロセス管理の促進に役立ちます。

モデル: 実物の物理的特性または機能特性を含む、計画中または完成したアセットのデジタル表現。ワークフローの段階に応じて、データベースまたは本格的なパラメトリック3Dモデルになることもあります。これはBIM情報の集約から得られる具体的な成果物であり、重要なコストとスケジュール管理ツールであると考えてください。

管理:取得したBIMデータは、建設業界の厳格な基準に対するトレーサビリティとコンプライアンスを確保するために使用できます。設計・施工と企業のより広範な業務との橋渡しを行うことで、規模に応じた十分な情報に基づく意思決定が可能になります。

BIMに関連する規格とは?

BIMへの準拠に関しては、どこで事業を展開しているかによって大きく異なります。しかし、慎重に検討すべき重要なグローバル規格がいくつか存在します。

ISO 19650は、設計、引き渡し、データ管理、セキュリティなど、BIMライフサイクル全体にわたる一連の国際規格に対応しています。これらは、英国で開発された別の標準規格であるPAS 1192に基づいています。例えば、PAS 1192-3は、各プロジェクトの運用段階全体にわたる情報管理に対応しています。これらの規則の多くは、特に歴史的建造物の修復時に今でも使用されており、把握しておくことが重要な項目です。

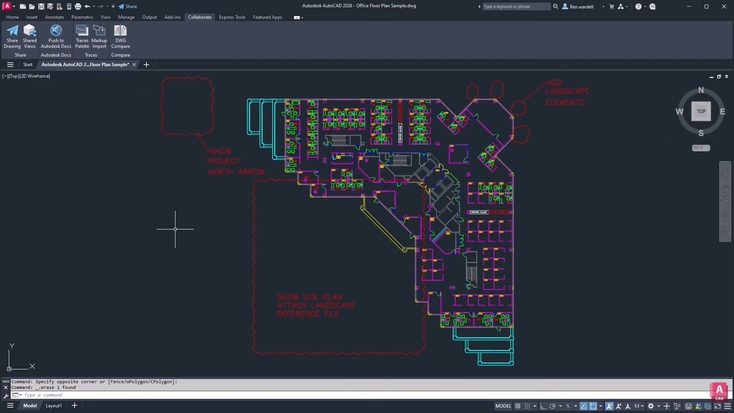

ここで言及する価値のあるもう一つのISO規格はISO 16739です。これは、BIMの相互運用性のための業界標準クラス(IFC)を定めており、異なるソフトウェア間でのコラボレーションに不可欠です。例えば、AutoCADやAutodesk Revitのようなソフトウェアは、データを損失することなく連携できることが求められます。

3Dモデリングとの関連性は低いものの、知っておくべき重要なものとして、COBie(Construction Operations Building Information Exchange)があり、これは非グラフィカル情報に対するBIMと同等のものに対応しています。実際には、特に公共インフラが関わる場合、機器リストや保証書などはBIMモデルからスプレッドシート形式で共有されることがよくあります。

ISO 19650の原則をローカルのフレームワークに効果的に落とし込んだ他の規格もいくつかあります。つまり、事業を展開している国のBIM規格要件について理解を深める必要があるということです。

BIMの異なる「レベル」

これらすべては少し複雑に聞こえるかもしれませんが、業界にはBIM統合の異なるレベルがあるため、企業が実際にどの程度統合されているかが判断できます。以下は、その段階の概要です。

レベル0: コラボレーションなし – デジタル化はほとんどまたは全くなく、建築家、エンジニア、請負業者間の統合もほとんどありません。情報は図面などの従来の形式で共有されるか、品質保証のための追跡が最小限の2Dレイアウトで共有される可能性が高いです。

レベル1: 部分的なコラボレーション – 一部の情報管理が導入され、初期段階では2D図面が使用され、可視化のために3D設計が展開されます。これにより、AutoCAD (3D)、SketchUp、MicroStation などのツールが使用されるようになります。共通のサーバが存在する場合でも、モデルの共有と統合の方法には制限がある可能性があります。

画像出典: https://www.youtube.com/@autocad

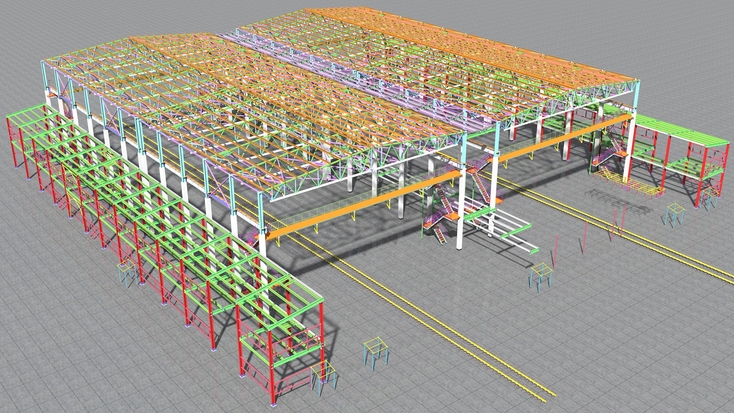

レベル2: 協働BIM– これは、多くの契約の調達に必要な BIM 統合のレベルです。英国では、国家インフラプロジェクトに必要とされることが多いです。情報豊富な3Dモデルが必須であり、標準プロセスを通じて汎用形式でデータが交換されます。設計において、エンジニアは依然として個別の3Dモデルを持つ可能性がありますが、干渉チェックのために統合されます。

レベル3: 完全統合BIM – 基本的に、最高レベルに到達するには、企業がすべて完全に統合され、全員がリアルタイムで共有デジタルツインから作業する必要があります。これは、データの均一性とコンプライアンスを確保する形で、完全なライフサイクルに対応する必要があります。

BIMの応用

設計と可視化

すべての設計プロセスと同様に、建物の設計・施工はコンセプト段階から始まります。専用ソフトウェアを使用することで、現実的な3Dのビジュアルを迅速に作成できます。用途に応じて、初期設計チェックのためのパラメータをオーバーレイ表示したり、壁、床、またはより複雑なシステムなど、平行面のパラメトリックモデリングが可能になります。

この段階で実施される「干渉チェック」も、効率性において非常に重要です。重複する設計間の衝突を自動的にチェックすることで、やり直しや現場でのエラーによるプロジェクトの中断を最小限に抑えながら、潜在的な問題を特定し修正できます。初期段階では、プロジェクトコンサルタントとの連携を保つことも同様に重要です。そのため、初期モデルは調整を支援します。

施工計画

BIMモデルは、詳細な分析プロセスに立ち入ることなく、設計と施工をプロジェクト予算に動的にリンクすることで、正確な予測を可能にします。このようなモデルを時間とシーケンスデータと統合することで、プロジェクトのシミュレーションが可能になり、機械の動線における潜在的な重複を特定し、進捗状況をリアルタイムで監視することが容易になります。

なんといっても、リアルタイムの計画はBIMの基礎です。厳密なアセット管理は、プロジェクトコストとリードタイムの削減に役立つだけでなく、企業出資者との連携維持にも貢献します。また、各建物の環境への影響を分析することも不可欠であり、これは業界にとって高まる懸念事項です。

現状検証

レーザスキャナやフォトグラメトリを使用することで、構造物をキャプチャし、元の設計と比較することができます。並べて比較することは、位置ずれや寸法/公差の問題、および建物から完全に欠落している要素を特定するのに役立ちます。設計意図が守られることを確保することで、床の高さや壁の厚さなど、構造要素によって引き起こされる問題を最小限に抑え、時間とコストのかかるやり直しを防ぐことができます。

現状スキャンは、より広範なプロジェクト管理の観点からも非常に価値があります。リアルタイムのモデルがあれば、アセットのトラッキングとコスト計画がはるかに容易になります。何かエラーが発生した場合、ワークフロー全体をカバーするデータセットがあれば、どこで問題が発生したかを示すことができ、同様に有用です。

スマートビルディングの統合

この概念に馴染みがない方のために説明すると、「スマートビルディング」とは、制御の一元化、自動化、パフォーマンスの最適化を行う高度な相互接続システムを組み込んだ構造物のことです。工場内では、これはモノのインターネット(IoT)ネットワークの構築を意味する場合があります。物理的な機械、センサー、ソフトウェアを接続することで、自動監視と迅速な意思決定が可能になります。

スマートビルディングの他の形態には、HVAC、エレベーター、アクセス制御システムなど、より従来型の技術が含まれます。いずれの場合も、BIMモデルは単一の統合されたデータセットを提供し、複雑に重複するシステムの設置と構成を容易にします。また、実用的なメリットもあります。例えば、照明、暖房、空調などは、実際の状況に応じて自動調整できます。

スキャン・トゥ・BIM:3Dスキャンが役立つ仕組み

BIMモデルと3Dモデルは同一ではないことを改めて強調することが重要です。後者には重要なテクスチャやジオメトリの詳細が含まれる場合がありますが、壁、ドア、設備などをカバーする、より広範なプロジェクトにわたるBIMデータセットほど多くの情報は含まれていません。

とはいえ、3DモデルはBIMモデルを作成するための基礎として使用できます。3Dスキャンは、既存の構造物に建設を行う際の貴重なツールです。現状条件の検証を可能にし、干渉チェック、迅速な文書化、コンテキスト分析を促進します。施工完了後も、3Dスキャンはインフラの検査と監視に使用できます。

例えば、Artec Ray IIは防潮壁の検査に使用され、Artec Evaはタービン製造のためのサブミリメートル精度のCADデータを取得することで、水力発電ダムの改修を支援しました。

測量やSLAMなどの技術と比較して、構造化光とLiDARはより多用途で正確です。Ray IIは最大1.9mmの精度でシーンを取得し、Artec Leoのようなワイヤレスのハンドヘルド型デバイスは0.1mmの精度で細部をキャプチャします。Artec Studioは、ポイントクラウドを1つのステップで統合し、重要な箇所で微細な高精度を実現した大規模スキャンを可能にします。

これを実現するには、少し追加の作業が必要となります。物体や建物、またはエリアのスキャンは、サードパーティ製ソフトウェアにエクスポートしなければならないことが多くあります。しかし、このプロセスは実行が容易になってきており、設計や計画のためのRhino 3DからAutodesk Revitまで、多くの選択肢があります。現状データを必要とするあらゆるアプリケーションは、BIMワークフローにリアリティキャプチャを追加することでメリットを得ることができます。

BIM vs. CAD – どちらが最適で、今後の動向は?

3Dモデルと同様に、CADはBIMモデリングとは少し異なります。CADは、ほぼすべての設計・文書化の専門家にとって業界標準のモデリング形式です。一方、BIMは、複数の専門分野にわたるプロジェクトコラボレーションのためのデータが豊富なモデルを作成することに重点を置いています。

Artec Studioのオートサーフェシング機能により、3DスキャンデータをソリッドのCADサーフェスに変換することがますます可能になり、設計者はゼロから始める必要がなくなります。スキャンとCAD比較は、偏差解析や摩耗の監視にも最適です。最新バージョンのソフトウェアでは、メッシュだけでなく、ポイントクラウドにプリミティブをフィットさせることも可能になりました。これにより、現場での検証や検査アプリケーションに対して、組み込み測定ツールが効果的に開放されます。

今後は、スキャン・トゥ・CADまたはスキャン・トゥ・BIMモデルへの変換ソリューションが増加することが期待されます。しかし現時点では、これらは隣接し、時折重複するものの、別々のデータ取得分野を表しているのが現状です。

こちらを次にお読み下さい

ラーニングセンターに

さらに詳細が記載されています

あなたにとって、部屋をスキャンする目的はなんですか?また、それを実行する際に注意すべきことはどんなことでしょうか?まず第一に、部屋のスキャンに使用する3Dスキャナがそのタスクに適していることを確認することが重要です。このガイドでは、部屋をスキャンする目的、方法、それに最適な3Dスキャナ、そして他に考慮すべき事項について説明していきます。

昨今、AIやVR、そして3Dスキャンなどの高度技術が製造業にますます統合されてきていますが、物理的世界と仮想的世界の境界線はかつてないほど曖昧になっており、現在私達は第4次産業革命の時代にいると言う人さえいます。この「産業 4.0」の改革で中核となるのは、パフォーマンスの追跡や改善に使用できる部品、物理的なアセット、システム、またはプロセスの仮想コピーである「デジタルツイン」です。こちらの記事では、これらのデジタルツインがどのように作成されるのか、どこに適用されるのか、そしてそれらが将来活用される可能性がある分野について説明していきます。

様々な業界でレンダリング用ツールに対する需要が前例にないほど高まっている昨今、最新の3Dレンダリングソフトウェアではあらゆる種類のプロジェクトに対応する幅広いオプションを提供しています。3Dレンダリングはかつては高予算の制作にのみ使用されていましたが、現在ではほとんどの設計作業に不可欠となっており、3Dモデルを鮮明な3Dまたは2Dのビジュアルに変換します。本記事は、現在における最高の3Dレンダリングソフトウェアに関する総合的なガイドとして各製品の長所と短所を比較し、それぞれのニーズに最適なソフトウェアを見つける支援をします。まず始めに、3Dレンダリングとは一体何かという概要から説明していき、それから現在市場で入手可能な一般的なオプションをいくらかリストアップして、みなさんにとって最適なソフトウェアを選択する上で注意すべき点をご紹介します。